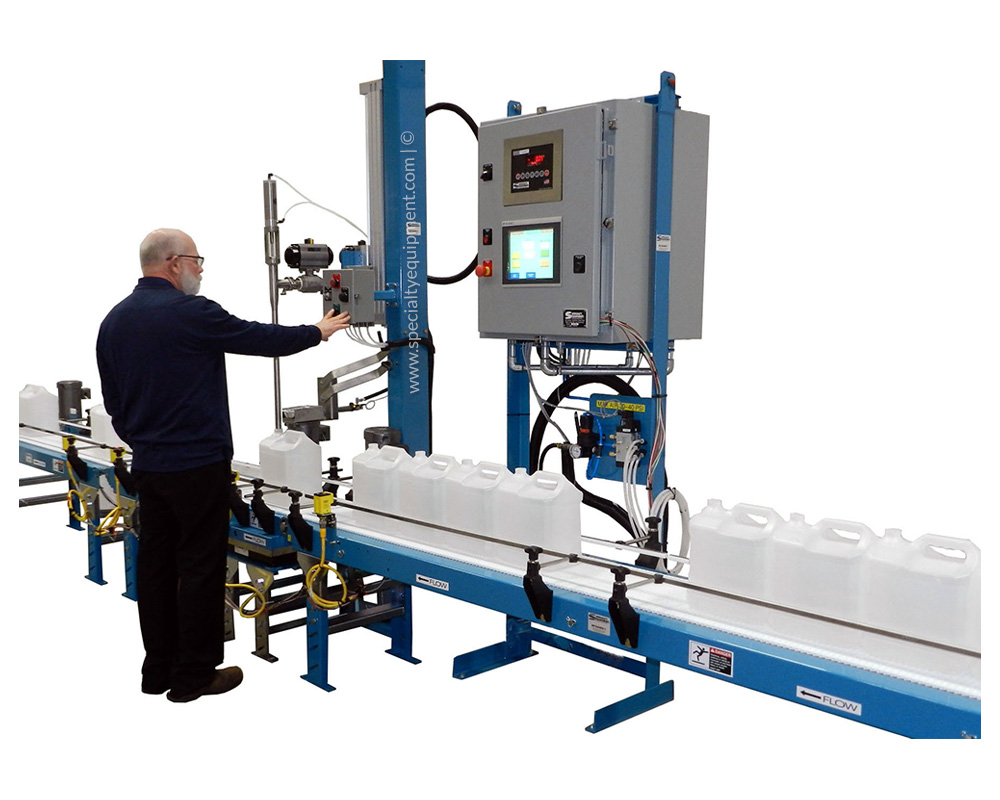

Pail Filling System – Semi-Automatic

This basic semi-automatic pail filling machine was designed for top and sub-surface pail filling for 1 to 7 gallon pails, jerricans, jugs, kegs, etc. The filler will use from 3/4″ to 1.9” diameter lances depending on the containers. Sanitary specs are available.

Model: PF-510

Rate: 4 pails per minute, depending on viscosity

Container: 1 to 7 gallon pails, jugs, cans etc.

Material: Carbon or stainless steel construction, all wetted parts use 316 stainless steel

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | No |

| Conveyor System For Empty And Full Containers | Standard |

| Foaming Product | Yes |

| Automation Type | Semi-Automatic – Operator positions lance to container or container to lance |

| Product Temperature | <250 |

| Container Type (Standard) | Pails |

| Container Type (Optional) | Drum-Plastic, Drum-Steel, Quarts |

| Fill Heads (Standard) | 1 Fill Head |

| Fill Heads (Optional) | 2 Fill Head, 3 Fill Head, 4 Fill Head |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Classification for Explosive / Flammable Environments (Optional) | Class I – Div I, Class I – Div II |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment, Food Grade, Outdoor, Requires Washdown |

| Frame Construction / Coating (Standard) | Carbon Steel Enamel |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 304, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | Corrosive / Caustic, Food Grade |

| Product Viscosity Handling (Standard) | 0-2,500 CPS (Water to Maple Syrup), 10,000 CPS (Honey), 100,000 CPS (Toothpaste), 50,000 CPS (Ketchup) |

| Product Viscosity Handling (Optional) | 250,000 CPS (Peanut Butter) |

Overview

This basic semi-automatic pail filling machine was designed for top and sub-surface pail filling for 1 to 7 gallon containers up to 19″ tall. The machine will typically use from 3/4″ dia. up to a 1.9” diameter lance depending on the bung opening of the containers.

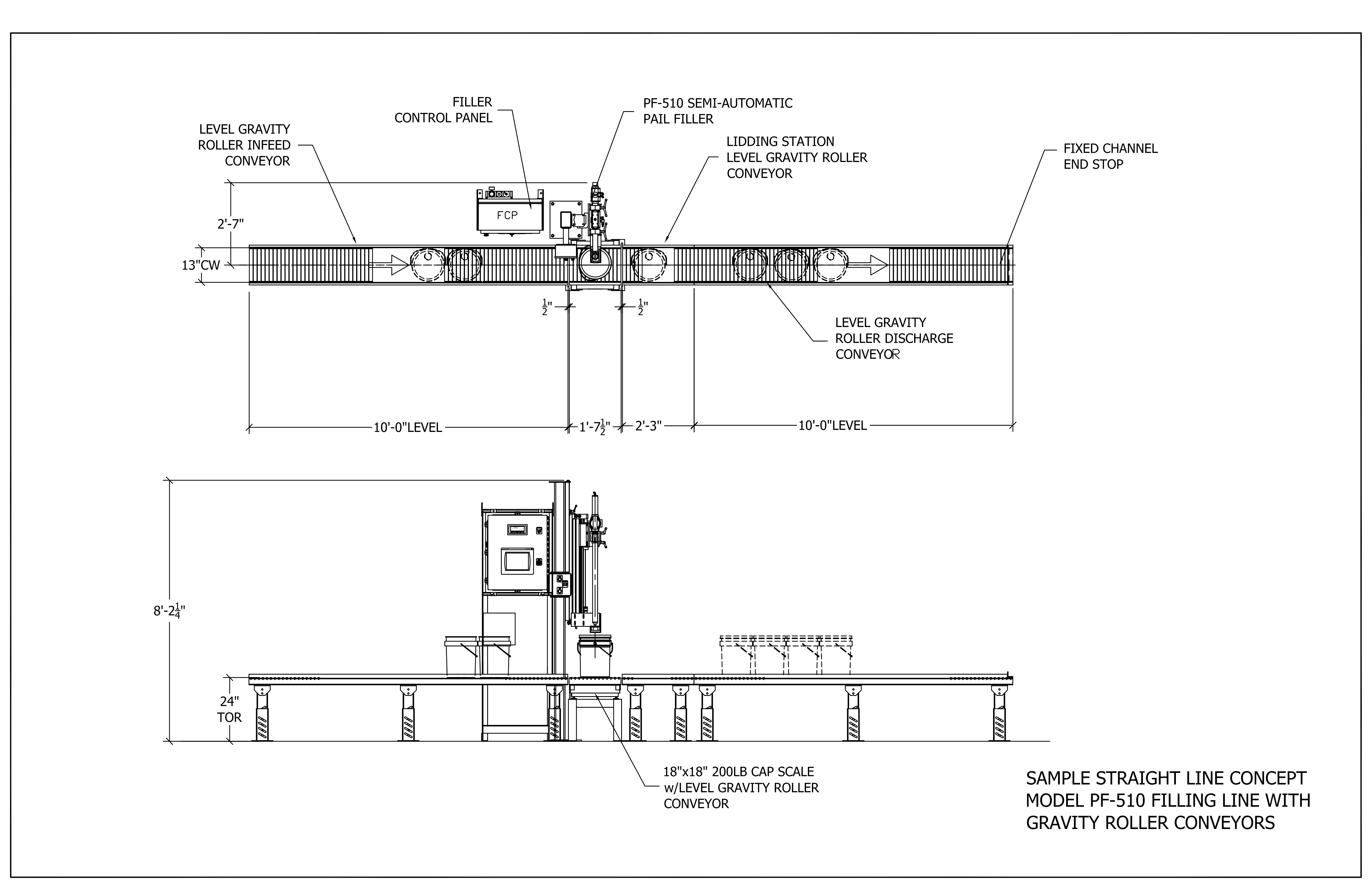

The application shown above is a free-running, push-along system with five components;

- Gravity roller infeed accumulation conveyor

- Model PF-510 semi-automatic, top and sub-surface pail filler

- Gravity roller conveyor on the scale

- Gravity roller conveyor after the filler for a lid and label station

- Gravity roller discharge accumulation conveyor

Description of Operation

This is a model PF-510 top and a sub-surface filling machine.

- Empty containers are placed onto the infeed conveyor to accumulate

- The operator pulls a container onto the filling station and presses start

- The lance will insert to the bottom of the container, if sub-surface filling

- The controller will zero the tare weight before the fill cycle begins

- When the fill cycle is complete, the lance will rise to its home position

- A pneumatic drip pan will move into place to catch any residue

- The operator will move the filled container to the lid station

- Another empty pail will be pulled onto the scale conveyor

Specifications

This is a model PF-510, top and sub-surface filler for 1 to 7 gallon containers up to 19″ tall.

- Lance and all wetted parts are 316 stainless steel

- Filler has a three speed fill cycle; slow/fast/shot, if needed

- Two full-port ball valves are used to prevent hammering

- A 200 lb/100 kg capacity scale

- Communications port for interface with Drum Filler in the Cloud

- Scale accuracy +/- 0.05 lbs on 3 sigma curve

- NTEP approved scale and weight meter

- All controls enclosed in a NEMA 4 panel

- Controller is an Allen Bradley PLC

- Touch screen is an Allen Bradley, color Panel View

- Push buttons mounted at the fill station

- Automatic zero tare weight before filling starts

- Air cylinder raises and lowers the lance

- Pneumatically operated drip pan

- Safety interlock, no container, no fill

- Auto abort, lance crash protection

- A 2’-0” long gravity roller conveyor is on the scale

- A 2’-0” long gravity roller conveyor for the lid station

- Welded structural steel filler stanchion