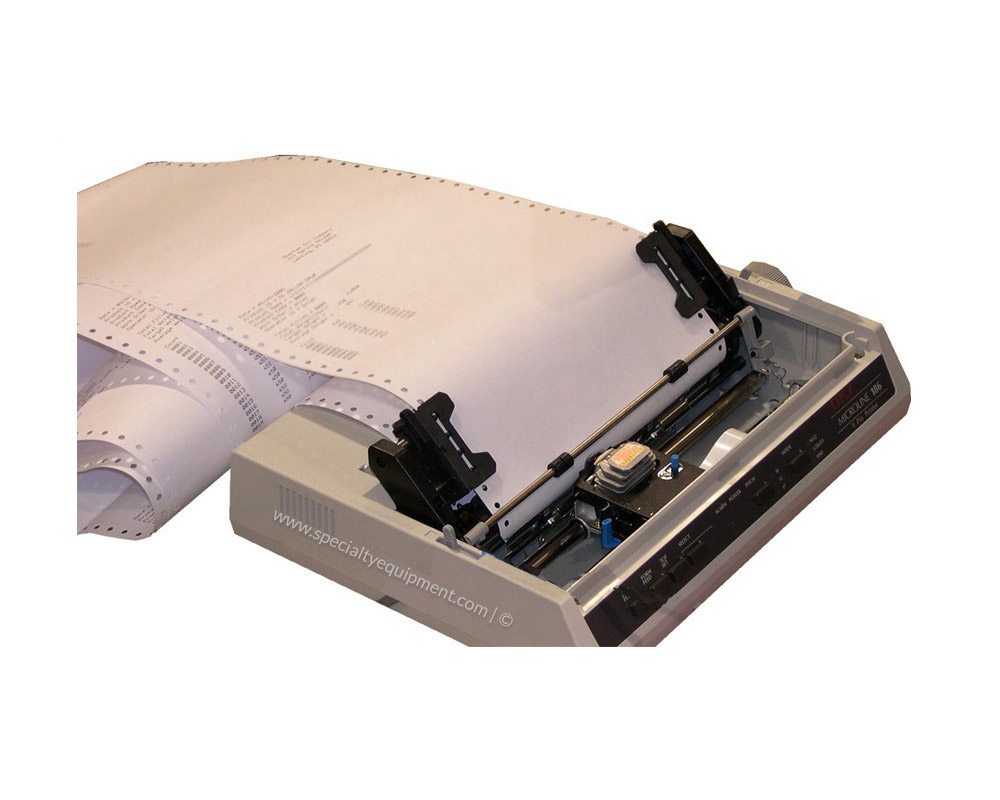

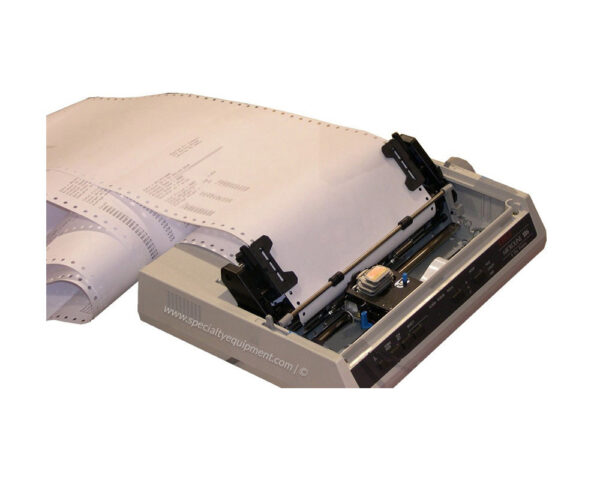

Data Printout

Product Details: Item No. 29

Components: Okidata or Epson printer, paper, programming, and platform stand

Material: Steel, plastic and paper

Overview

If you require constant data and information about your filling operation this option provides the necessary data from the filling operation and can be sent directly to the company mainframe, or a hard copy report can be provided anywhere you desire. Either method can be added to you existing filling operation.

The information is provided by way of a RS232, 2400 BAUD data string for interface to a serial printer or recorder of choice. The data collected from the filling operation is sent to an Okidata printer that prints out a continuous paper flow, or on separate sheets, as shown above. Alternatively, an Epson printer can be provided to generate a tape, or tickets, as needed.

Technical Specifications

The data collected from the filling operation is sent to an Okidata printer that prints out a continuous paper flow, or on separate sheets. Alternatively, an Epson printer can be provided to generate a tape, or tickets, as needed.

- All the hardware and programming is provided:

- Up to 250 product menu codes

- Operator and product name with codes and ID

- Consecutive container count of each fill

- Time and date of the operation

- Gross, net, and tare weight of each container

- Sub-total and total weight of each container

- Average container weights of each container

- Number of partial filled containers