Ready To Ship

At Specialty Equipment, we know businesses don’t always have the luxury of long lead times when it comes to liquid filling equipment. Don’t put your operations on hold or risk losing a contract due to lack of equipment.

Ready to Ship™

We have three different liquid filling solutions that are available to be crated, loaded, and delivered to your business. Learn more about these three units to find which solution is the best for your requirement.

Mobile Pail Filler

This mobile pail filler was created for batch filling operations at multiple locations. It is a top and sub-surface pail filler that moves around on casters.

Product Details: Item No. 120

Model: MPF-510

Rate: 4 to 5 pails per minute depending on product viscosity

Container: 1 to 7 gallon pails, jugs, cans, etc.

Material: Carbon or stainless steel construction, all wetted parts use 316 stainless steel

Palletized Drum/Tote Filler - Stand Alone

This stand-alone, palletized drum & tote filler is both a top and sub-surface filling machine, designed for batch operations.

Product Details: Item No. 101

Model: DF-5540

Capacity: 3, 4, or 5 drums per pallet or an IBC

Container: 5 to 55 gallon drums or 275 to 550 gallon IBC’s, containers 20” to 80” tall

Material: Carbon or galvanized steel construction, all wetted parts use 316 stainless steel

Palletized Drum/Tote Filler With Conveyors

The most versatile and widely accepted filling machine is this palletized drum and IBC/tote filler. It is both a top and sub-surface liquid filling machine for filling a pallet of drums or a single IBC/tote ranging from 5 to 550 gallons.

Product Details: Item No. 102

Model: DF-5540

Capacity: 3, 4, or 5 drums per pallet or an IBC

Container: 5 to 55 gallon drums or 275 to 550 gallon IBC’s, containers 20” to 80” tall

Material: Carbon or galvanized steel construction, all wetted parts use 316 stainless steel

Productivity and Uptime is Critical

Since 1969, we have built our reputation on high quality, rugged machinery and high-caliber service to:

Improve efficiency and production levels

Increase processing speeds and maximum uptime

Reduce labor, handling and maintenance

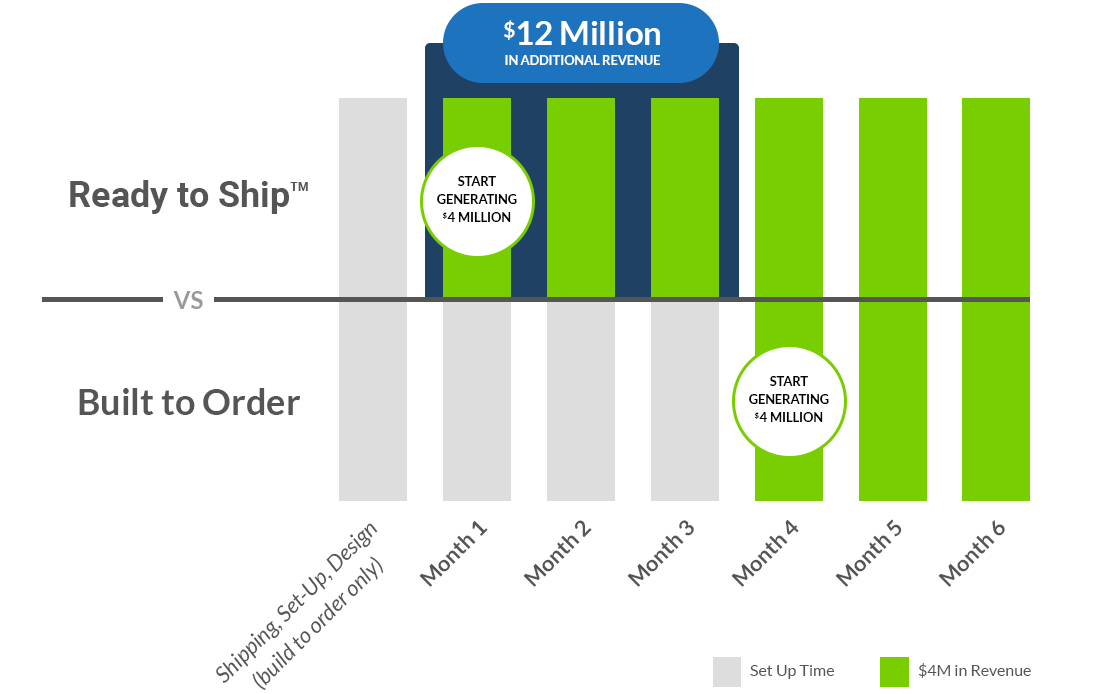

Want to see how quickly you can get to your goals with Ready to Ship™?

Fill out the prompts below and we will provide the timeline to your goal. How much money can you make packaging today vs starting in 6 months?

Results above are calculated by multiplying the product cost per pound by:

Pounds per drum * Drums per day

Pounds per drum * Drums per day * 5 Days per week

Pounds per drum * Drums per day * 4.33 Weeks per month

Pounds per drum * Drums per day * 12 Months per year