Pail Filling System – Semi-Automatic

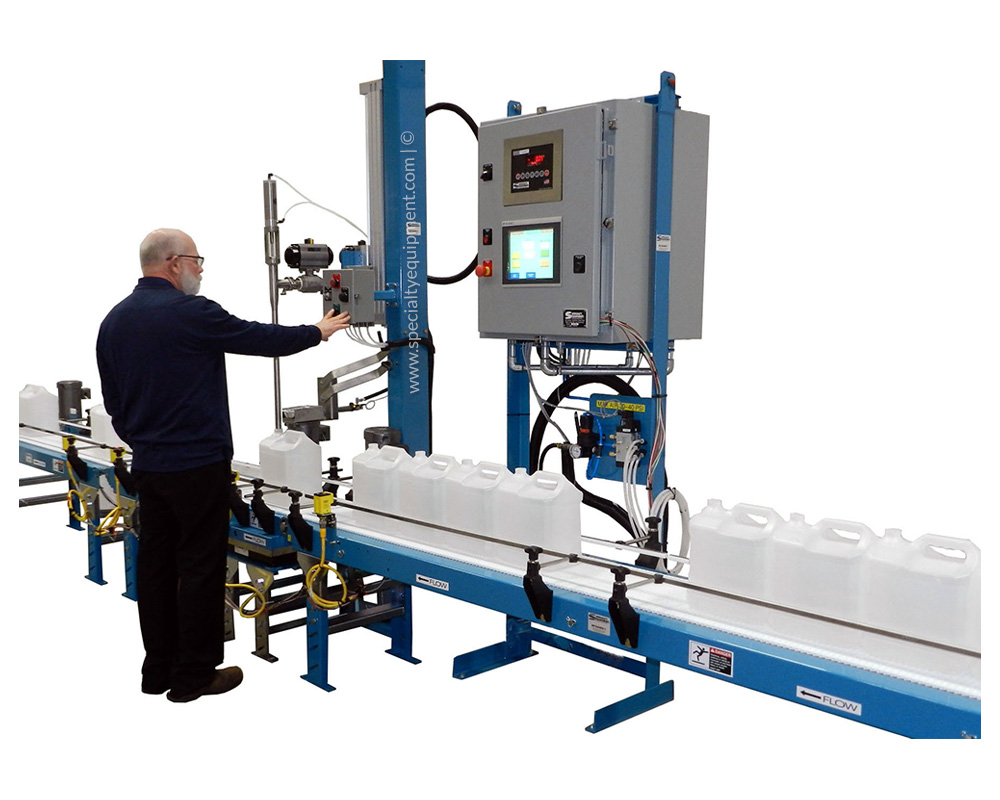

This basic semi-automatic pail filling machine was designed for top and sub-surface pail filling for 1 to 7 gallon pails, jerricans, jugs, kegs, etc. The filler will use from 3/4″ to 1.9” diameter lances depending on the containers. Sanitary specs are available.

Product Details: Item No. 118

Model: PF-510

Rate: 4 pails per minute, depending on viscosity

Container: 1 to 7 gallon pails, jugs, cans etc.

Material: Carbon or stainless steel construction, all wetted parts use 316 stainless steel

Overview

This basic semi-automatic pail filling machine was designed for top and sub-surface pail filling for 1 to 7 gallon containers up to 19″ tall. The machine will typically use from 3/4″ dia. up to a 1.9” diameter lance depending on the bung opening of the containers.

The application shown above is a free-running, push-along system with five components;

- Gravity roller infeed accumulation conveyor

- Model PF-510 semi-automatic, top and sub-surface pail filler

- Gravity roller conveyor on the scale

- Gravity roller conveyor after the filler for a lid and label station

- Gravity roller discharge accumulation conveyor

Description of Operation

This is a model PF-510 top and a sub-surface filling machine.

- Empty containers are placed onto the infeed conveyor to accumulate

- The operator pulls a container onto the filling station and presses start

- The lance will insert to the bottom of the container, if sub-surface filling

- The controller will zero the tare weight before the fill cycle begins

- When the fill cycle is complete, the lance will rise to its home position

- A pneumatic drip pan will move into place to catch any residue

- The operator will move the filled container to the lid station

- Another empty pail will be pulled onto the scale conveyor

Technical Specifications

This is a model PF-510, top and sub-surface filler for 1 to 7 gallon containers up to 19″ tall.

- Lance and all wetted parts are 316 stainless steel

- Filler has a three speed fill cycle; slow/fast/shot, if needed

- Two full-port ball valves are used to prevent hammering

- A 200 lb/100 kg capacity scale

- Communications port for interface with Drum Filler in the Cloud

- Scale accuracy +/- 0.05 lbs on 3 sigma curve

- NTEP approved scale and weight meter

- All controls enclosed in a NEMA 4 panel

- Controller is an Allen Bradley PLC

- Touch screen is an Allen Bradley, color Panel View

- Push buttons mounted at the fill station

- Automatic zero tare weight before filling starts

- Air cylinder raises and lowers the lance

- Pneumatically operated drip pan

- Safety interlock, no container, no fill

- Auto abort, lance crash protection

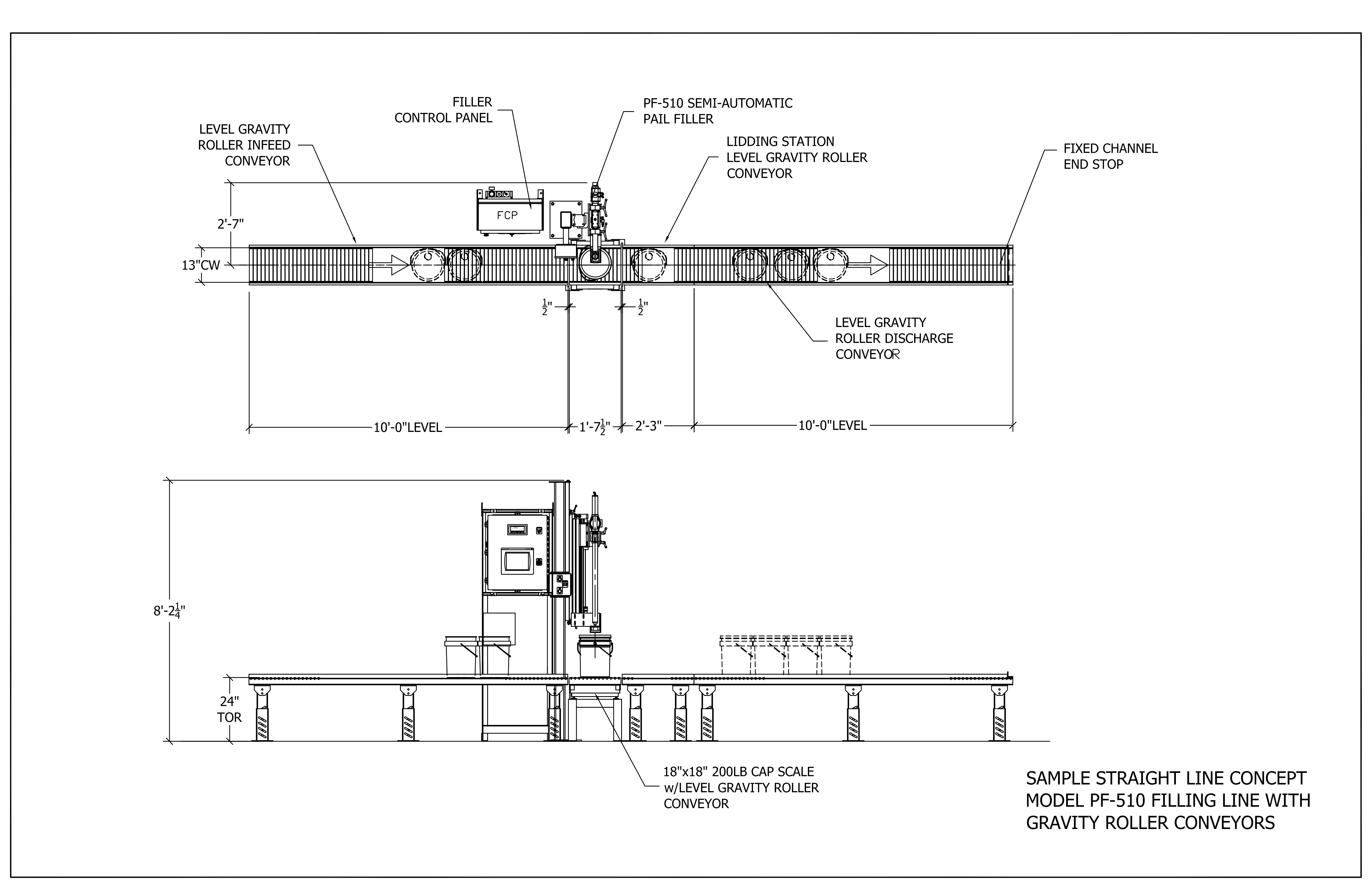

- A 2’-0” long gravity roller conveyor is on the scale

- A 2’-0” long gravity roller conveyor for the lid station

- Welded structural steel filler stanchion

Concept Drawing

A straight-line configuration is the most common for a pail filling system. This includes pail accumulation before the filler, one pail at the filler and another pail at the bung and label station. The amount of accumulation and length of conveyors are determined by the customer.

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | No |

| Conveyor System For Empty And Full Containers | Standard |

| Foaming Product | Yes |

| Automation Type | Semi-Automatic – Operator positions lance to container or container to lance |

| Product Temperature | <250 |

| Container Type (Standard) | Pails |

| Container Type (Optional) | Drum-Plastic, Drum-Steel, Quarts |

| Fill Heads (Standard) | 1 Fill Head |

| Fill Heads (Optional) | 2 Fill Head, 3 Fill Head, 4 Fill Head |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Classification for Explosive / Flammable Environments (Optional) | Class I – Div I, Class I – Div II |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment, Food Grade, Outdoor, Requires Washdown |

| Frame Construction / Coating (Standard) | Carbon Steel Enamel |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 304, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | Corrosive / Caustic, Food Grade |

| Product Viscosity Handling (Standard) | 0-2,500 CPS (Water to Maple Syrup), 10,000 CPS (Honey), 100,000 CPS (Toothpaste), 50,000 CPS (Ketchup) |

| Product Viscosity Handling (Optional) | 250,000 CPS (Peanut Butter) |