Stainless Drum & Tote Filler

This filling system was built for a food grade application, subject to wash down. The machine operates as a top and sub-surface filler, which allows a group of drums, a single IBC/tote, or a collapsible bin to be filled from 5 to 550 gallon. All the wetted parts comply with sanitary conditions.

Product Details: Item No. 50

Model: SDF-5540

Capacity: 3, 4, or 5 drums per pallet or an IBC

Container: 5 to 55 gallon drums or 275 to 550 gallon IBC’s, containers 20” to 80” tall

Material: Structural 304 stainless steel construction, all wetted parts use 316 stainless steel

Overview

This filler system was built for a food grade application, subject to wash down. The machine operates as a top and sub-surface filler, which allows a group of drums, a pallet of drums, a single tote, or a collapsible bin to be filled. An inner mast within the filler stanchion rises up and down to adjust the boom and filling lance to the height of the containers to be filled, which ranges from 5 to 550 gallon, or 20″ to 80″ tall. All the wetted parts comply with sanitary conditions and specs. All the necessary controls to operate the filler are on the handle in front of the operator.

In this application, the operator will also fill a collapsible container. To accommodate the flexible bin, a spreader bar with a cam-lock clamp is provided. The aluminum bar is placed across the width of the collapsible container to keep the sides upright during the filling operation, and also to hold the throat of the plastic bag in place during the fill cycle.

The video shows a standard filling operation.

Description of Operation

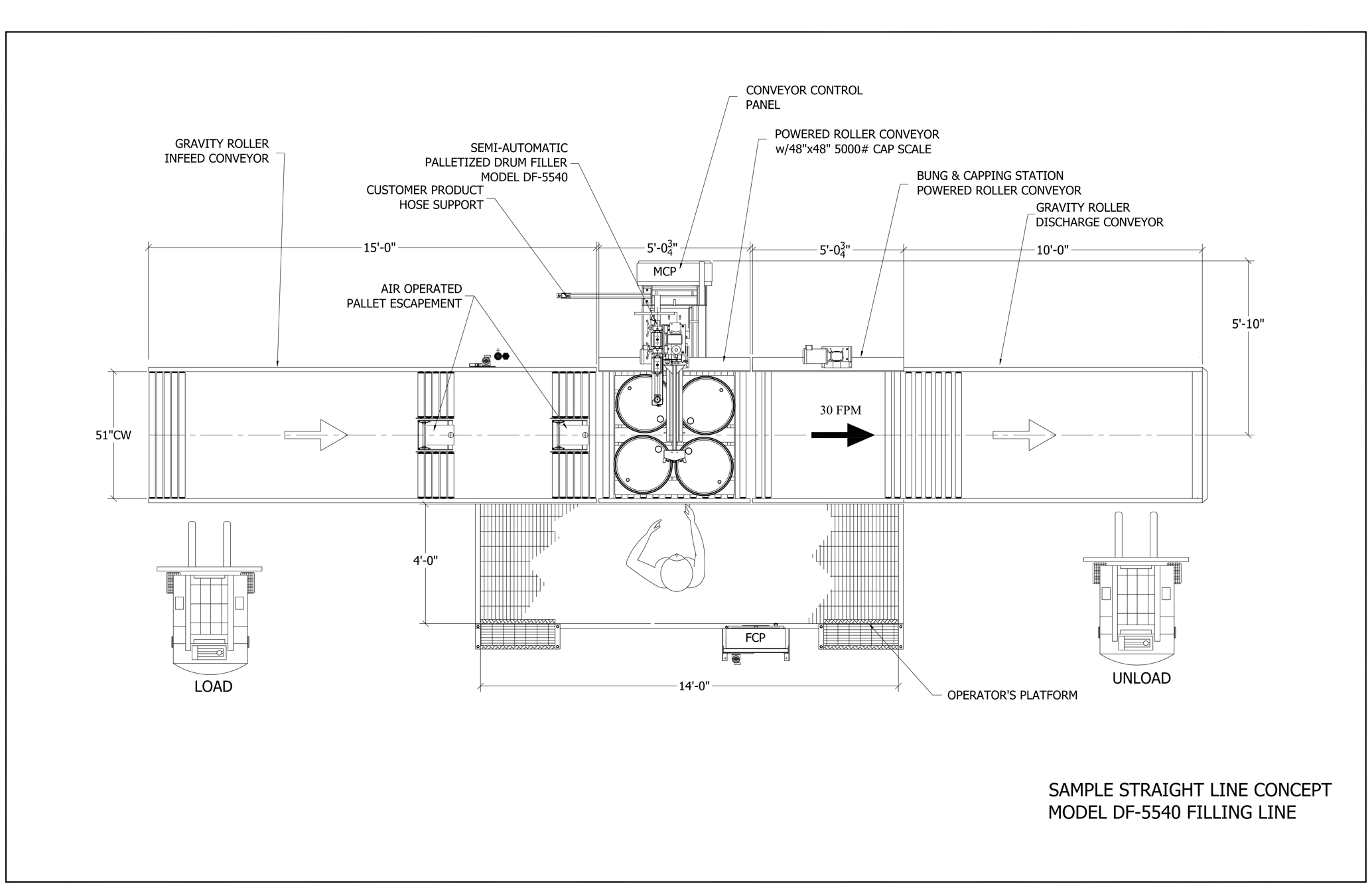

This all-stainless machine is a model DF-5540, a top-fill and sub-surface drum and tote filling system.

- When a full load is discharged, a new load of empties conveys to the fill station and stops

- The operator button releases the boom to guide the lance to any drum he chooses

- The operator releases the button and the boom is automatically locked in place

- By pressing the start button, the lance travels to the bottom of the drum

- The machine will automatically zero the tare weight before the fill cycle begins

- The filler has three speeds, slow/fast/slow, if needed

- If filling a foaming product, the fill cycle will start on slow fill

- When the liquid reaches the tip of the lance, the machine automatically shifts into fast fill

- Near the top, the machine cycles to slow, to top off the container and minimize foaming

- When filled, the lance automatically retracts to its home position.

- The operator button again releases the boom and guides the lance to the next drum

- Fills a 55 gallon drum with water in 45 seconds at 80 gallons per minute product flow

Technical Specifications

This filler system was built for a food grade application, subject to wash down. The machine operates as a top and sub-surface filler, which allows a group of drums, a pallet of drums, a single tote, or a collapsible bin to be filled.

- All wetted parts meet sanitary, food grade conditions

- Two infeed full-port ball valves prevent product hammering

- Scale is a 5,000 lb capacity platform type

- Controller is an Allen Bradley PLC with a 250 product menu

- Touch screen is an Allen Bradley color Panel View

- The filler has a three filling speeds; slow/fast/shot, if needed

- Air operated drip pan with a UHMW wiper ring

- Built in fume hood at the lance for vapor collection

- Air cylinder to raise and lower the fill lance

- Heavy duty brakes for boom position locking

- NTEP approved scale and weight meter

- NEMA 4 standard enclosure, others optional

- Communications port for interface with Drum Filler in the Cloud

- Automatically will zero tare the weight before filling container

- Operator troubleshooting interface with prompts

- Automatic abort if lance is not aligned with bung opening

- Rugged, all-welded stainless steel construction

- All stainless steel conveyors with wash-down duty motors

- Fills a 55 gallon drum with water in 45 seconds at 80 gallons per minute product flow

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | No |

| Conveyor System For Empty And Full Containers | Standard |

| Foaming Product | Yes |

| Automation Type | Semi-Automatic – Operator positions lance to container or container to lance |

| Product Temperature | <250 |

| Container Type (Standard) | Drum-Plastic, Drum-Steel, Palletized Drums (Plastic), Palletized Drums (Steel), Totes / IBCs up to 330 gallons (with 5" conveyable foot) |

| Container Type (Optional) | Pails, Totes / IBCs up to 5,500 gallons (with 5" conveyable foot) |

| Fill Heads (Standard) | 1 Fill Head |

| Fill Heads (Optional) | 2 Fill Head |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Classification for Explosive / Flammable Environments (Optional) | Class I – Div I, Class I – Div II |

| Site Conditions (Standard) | Corrosive Environment, Food Grade, Industrial Standard, Requires Washdown |

| Site Conditions (Optional) | Outdoor |

| Frame Construction / Coating (Standard) | Stainless 304 |

| Frame Construction / Coating (Optional) | Stainless 316 |

| Product - Wetted Parts (Standard) | Food Grade, Standard 316 |

| Product - Wetted Parts (Optional) | Corrosive / Caustic |

| Product Viscosity Handling (Standard) | 0-2,500 CPS (Water to Maple Syrup), 10,000 CPS (Honey), 100,000 CPS (Toothpaste), 50,000 CPS (Ketchup) |

| Product Viscosity Handling (Optional) | 250,000 CPS (Peanut Butter) |