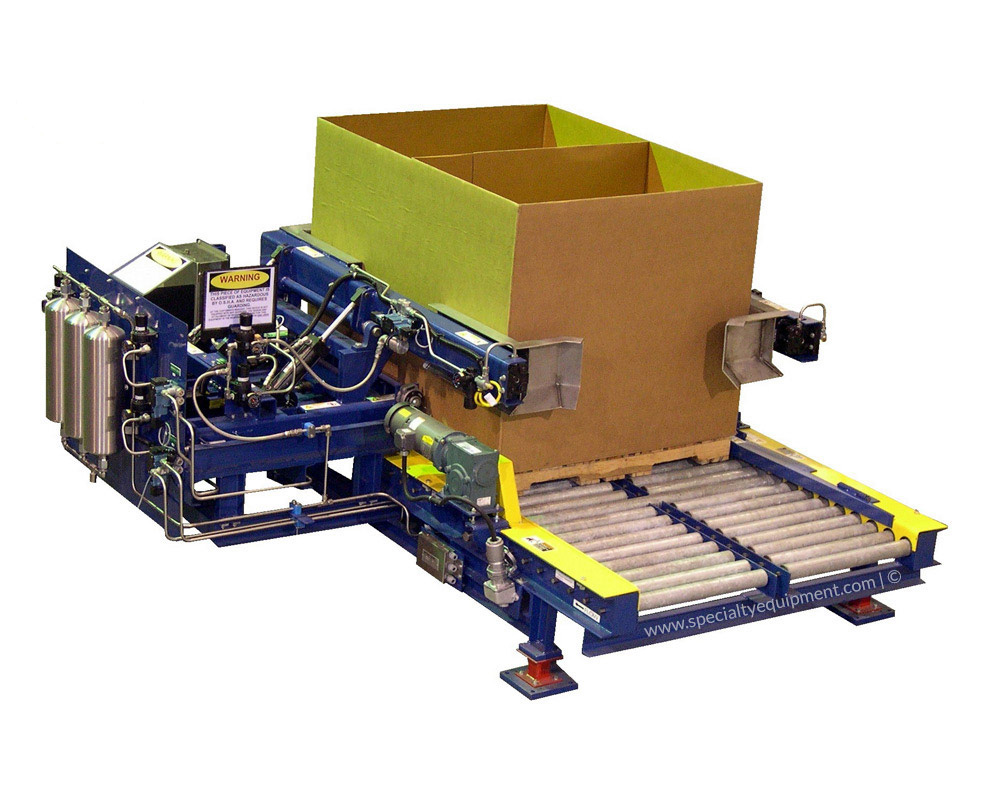

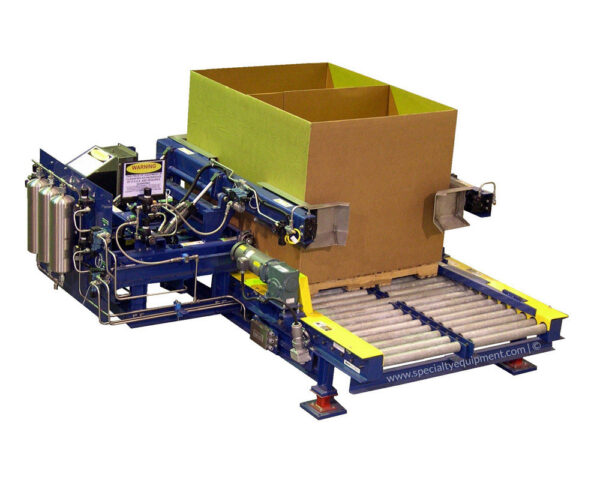

Custom Conveyor

Product Details: Item No. 805

Capacity: 4,000 lbs. per pallet, box, or IBC load

Use: For conveying, holding and filling a bulk box with 80 lb cubes

Material: Stainless or carbon steel construction

- Overview

- Description of Operation

- More Alternative Equipment

- Product Details

- Technical Specifications

Overview

Here is a custom designed bulk box loading station, otherwise known as a (BAD), Box Alignment Device. It positions and holds a bulk box for a high speed robot that will fill the box with 80 lb cubes.

When a bulk box is conveyed into the machine, the twin arms swing down to square up and position the front end of the box. Other air-operated mechanisms are used to lock the box in place. The conveyor is synchronized with a common drive shaft, transferred by a solid roller. Once squared in the front, the end clamps then close in on the box, pushing it to the right, to square up that side. The machine then signals the robot to start loading the box with cubes.

Description of Operation

This is a custom-made conveyor device, (the first of many) used at a box loading application.

- A made-up bulk box conveys into the B.A.D. machine

- The conveyor has a common, solid drive shaft to transfer power to the other side

- An air operated squaring device is normally up to stop the front end of the box

- A pair of air cylinders pushes the box to square up one side

- Air operated arms pivot into position on both sides of the box

- A pneumatic cylinder activates to capture the box

- A signal is then sent to the robot to start

- When completed, the robot signals the B.A.D. machine to free-up the box

- The front squaring device is then lowered

- The double clamps retract the end plates then swing back to free the box

- When completed, a signal is sent to the roller conveyor to start

- The conveyor drive the box straight ahead and signals for another