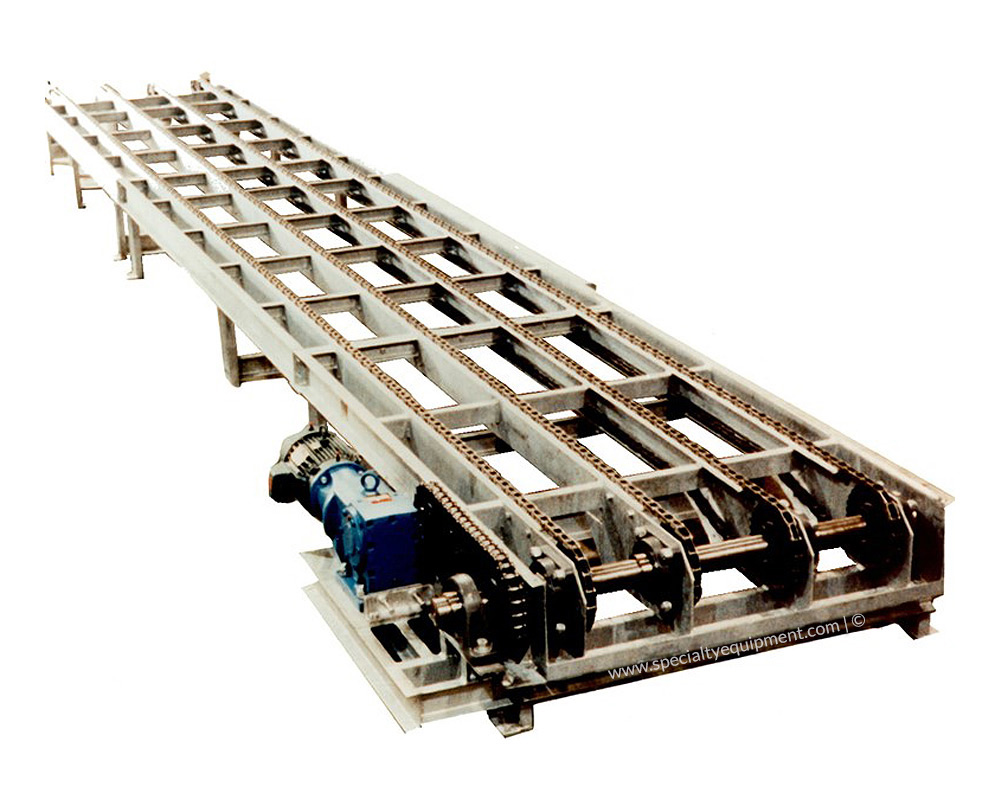

Chain Conveyors for Heavy Loads

Product Details: Item No. 145

Capacity: 5,000 to 10,000 lbs per unit load

Use: For heavy, wrong-way pallets and other heavy loads not conveyable on rollers

Material: Galvanized, carbon, or stainless steel construction

Overview

Choosing a chain conveyor is determined by need for load stability, when rollers are not sufficient, when pallet boards or tote runners are conveying the wrong way, when the loads are transferred, or when crossing-over is necessary. This twenty-five foot long, heavy duty, four-strand chain conveyor is for handling unstable loads up to 5,000 lbs each. The customer uses it outside of a foundry, for bins of hot forgings to index and accumulate while cooling down. The frames are galvanized and the chain is self lubricated. Proper OSHA safety guarding, although not shown here, was applied.

Technical Specifications

This four-strand chain conveyor is twenty-five feet long and carries two large bins of forgings, 5,000 lbs. each bin

- Carrying chains are 2080 double-pitched roller chain

- Rollers of the chains ride on hardened key stock

- B-type sprockets are keyed & bored for a 2.5″ shafts

- Drive is floor mounted, 1 HP right angle gear motor for 20 FPM

- Frames are 8″ galvanized channels welded with cross members

- Supports are 4″ galvanized structural channels welded to frames

- Conveyor capacity is 5,000 lbs per unit load

- OSHA approved guarding, (not shown) is provided

Conveyors are manufactured with structural steel frames and supports welded together, making each unit a one-piece superstructure, the most rugged standard in the industry.