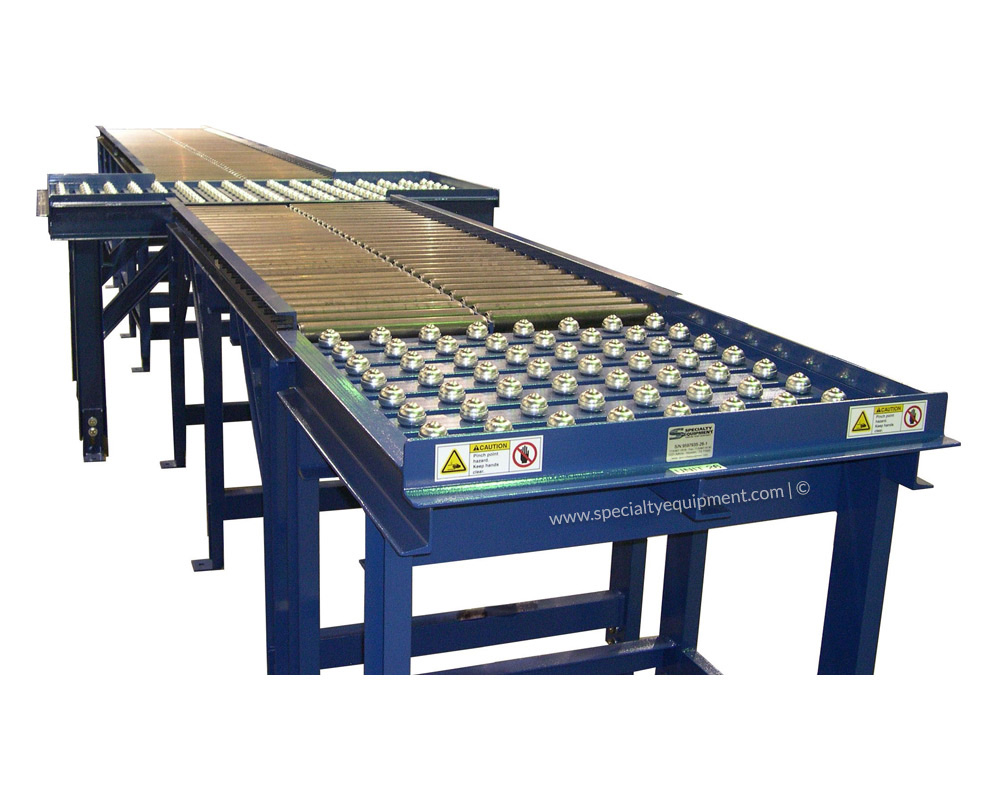

Ball Transfer Conveyor

Product: Details Item No. 154

Capacity: 250 lbs per unit load

Use: For manually transferring and reorienting flat bottom items, like as a work or inspection station

Material: Carbon, galvanized, or stainless steel construction

- Overview

- Description of Operation

- Technical Specifications

- More Alternative Equipment

- Product Details

Overview

Ball transfer tables are commonly used to transfer sturdy bottom loads in any direction, or to rotate loads at a work station. The application shown above handles a forging resting on an 18″ square, smooth bottom board. Ball transfer table typically interfaces with roller conveyors.

Generally, loads moved on ball transfers max out at 250 lbs and only if the object has a smooth, hard bottom. It should also be noted that every ball transfer table must have a barrier on any side not being used as a transfer point, to prevent product fall off. The force required to move a 100 lb smooth bottom item across a ball transfer station is about 3 to 5 lbs inertia.

Description of Operation

Typically a ball transfer system connects with level gravity roller conveyors, allowing each load to reorient in any direction up to 360 degrees.

- Slave pallet, (square boards) up to 150 lbs are sent from a cutting machine

- The slave pallet being conveyed is a smooth 18″ x 18″ hard board

- The operator rotates the board for visual inspection of the payload

- If it passes inspection, the load is sent onto the westbound lane

- If it fails inspection the load is sent onto the eastbound lane

- If an item is to be flagged it will be pushed onto the northbound lane

- Often, a mark or label will be applied to each payload

- Typically, a load will pass by a work station every 90 seconds

Technical Specifications

A ball transfer conveyor usually connects with level gravity roller conveyors, allowing each load to reorient in any direction up to 360 degrees.

- Ball transfer sections range in length from 2′-6″ up to 10′ long

- Transfer section are 12″ to 60″ wide between frames

- Balls are 1″ diameter, on 3″ centers in a diamond pattern

- Balls are bolt-on type, mounted on a plate or channel strips

- Conveyor frames are 4″ x 5.4 lb/ft structural channels

- Supports are 4″ structural channels welded to the frames

- Ball conveyor frame capacity is 1,500 lbs per linear foot

- It requires only 3 to 5 lbs. inertia to move a smooth bottom object over a ball transfer conveyor