Chain Conveyors for Unstable Loads

Product Details: Item No. 146

Capacity: 2,000 lbs per unit load

Use: For gentle conveying and transfer of unstable and tall loads not conveyable on rollers or belts

Material: Carbon, galvanized, or stainless steel construction

- Overview

- Description of Operation

- Technical Specifications

- More Alternative Equipment

- Product Details

Overview

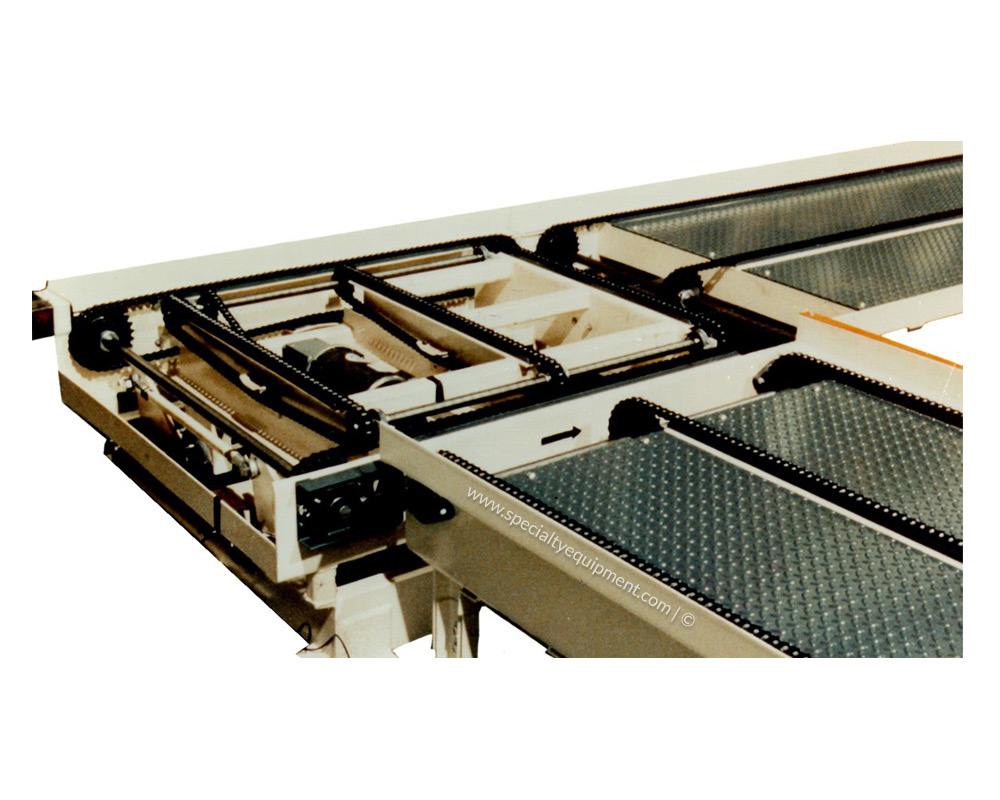

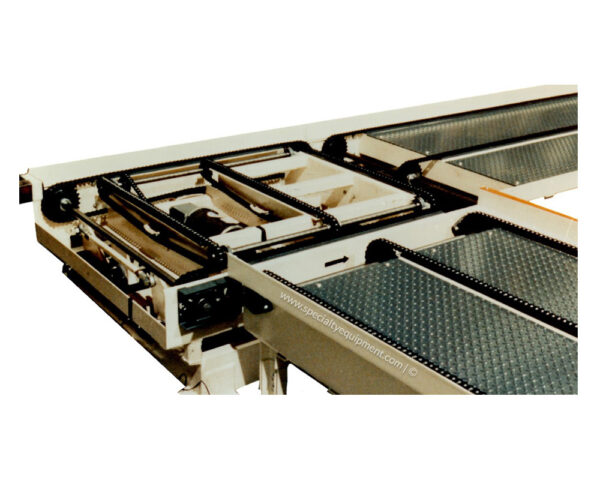

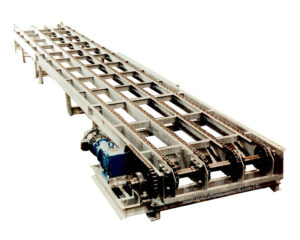

These multi-strand chain conveyors and 90 degree transfer were custom made for an eight foot high load that acted like a tower of Jell-O when it started, stopped and transferred.

We designed a three strand chain conveyor with slow start, ramp-up/ramp-down drives. Then an air operated two-strand jump transfer within a three strand chain conveyor. Ten chain transfers and twenty-two multi-strand chain conveyors were eventually installed. The results eliminated the customer’s problems and provided a four month payback.

Each conveyor had electric and pneumatic control of acceleration, deceleration, raising and lowering. The transfer rate is three loads per minute at weights up to 2,000 lbs.

Description of Operation

Each conveyor had electric and pneumatic control of acceleration, deceleration, raising and lowering. The 90° transfer rate is three loads per minute at weights up to 2,000 lbs

- Each transfer point, one of the chain conveyors is stationary

- When a load enters the transfer, a signal is sent to raise the transfer

- Air bags inflate to gently lift the load

- The chain conveyor starts in slow mode then ramps up to speed

- Before transfer is complete, the chains ramp down the slow speed

- A signal is given to lower the transfer and allow another to enter

- The cycle repeats at very transfer point

- The transfer rate is twenty seconds for loads up to 2,000 lbs

Technical Specifications

Each straight and right angle transfer conveyor has electric and pneumatic control of acceleration, deceleration, raising and lowering.

- All chains are RC 60 riding on UHMW channel guides

- All drives have ramp-up/ramp-down speeds

- Driven & take-up sprockets are B-type, keyed and bored

- Dive shafts are 1.5″ diameter with key ways

- Frames are 7 gauge welded formed steel

- All air bags are heavy duty type

- Flow control valves determine inflation speed

- Tread plates are for walking over, not standing

- The 90° transfer rate is three per minute with a 2,000 lb load