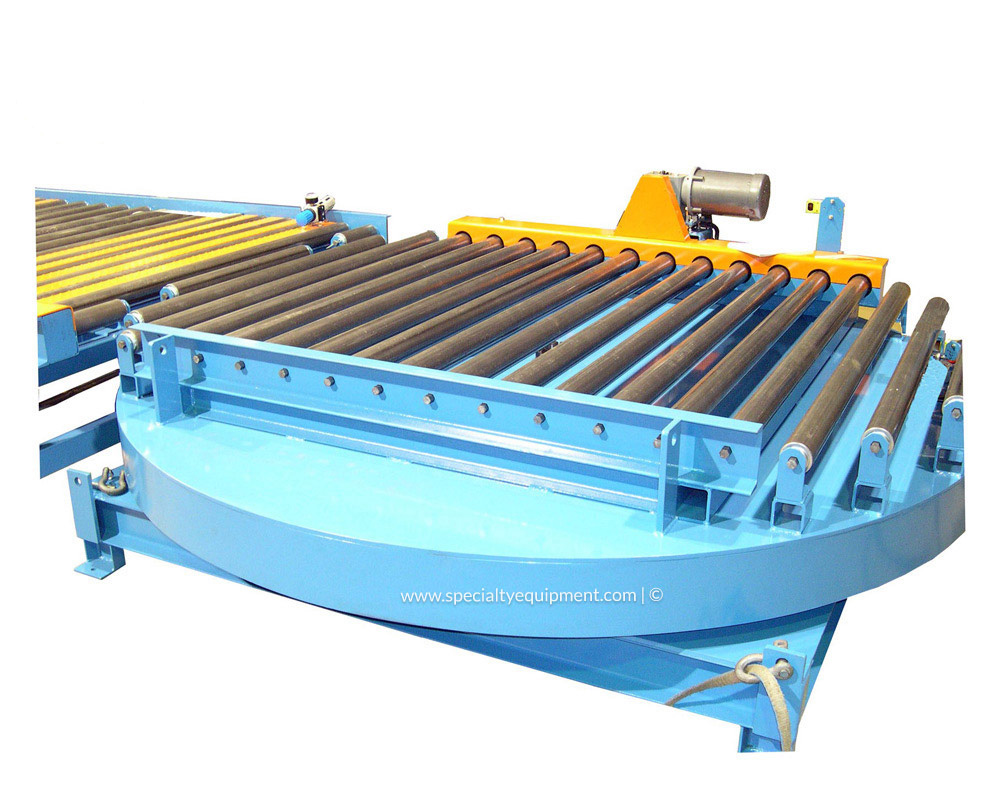

Powered Turntable

Product Details: Item No. 140

Capacity: 3,000 lbs. pallet, bin, or IBC

Use: For transferring, reorienting or changing direction of pallets, IBC’s, bins, etc.

Material: Carbon, galvanized, or stainless steel construction

- Overview

- Description of Operation

- Technical Specifications

- More Alternative Equipment

- Product Details

Overview

Turntables are used when the load needs to maintain orientation, as in a pallet, tote, or bin with bottom runners. The turntable can be a 90, 180, or 360 degree rotation, and can be air or electric operation. In the photo above, an air-operated turntable will maintain the pallet orientation and cycle it ninety degrees in thirty seconds.

A variety of conveyor types can be built onto the surface of any turntable. The most common is a chain driven live roller conveyor, as shown. Others are a wire mesh belt conveyor, and multi-strand chain conveyor surfaces. In either case, heavy duty turntables need special transitions to affect a smooth transfer at the entry and exit points.

The video below shows a heavy duty turntable in operation.

Description of Operation

The turntable can be a 90, 180, or 360 degree rotation, air operated or electric rotation. Special transition rollers are provided for a smooth transfer at the entry and exit points

- Bins or pallets are loaded onto the infeed end of the conveyor system

- As each load approaches a turntable, it looks for a clear signal to proceed

- The surface conveyor starts up and receives the load

- Upon signal that the load is on the turntable, the air cylinder is activated

- The air cylinder moves the turntable 90 degrees and stops

- A signal is given to start the surface conveyor again

- The load is driven off the turntable onto a main line conveyor

- The turntable receives a signal that the loads has cleared

- The turntable returns 90 degrees to it’s home position

Technical Specifications

This is a 4,000 lb capacity turntable to rotate 90 degrees by an air cylinder. Special transition rollers are provided for a smooth transfer at the entry and exit points

- The rotation stroke is by air cylinder activated

- Physical barriers at mounted at both ends of the stroke

- Four heavy duty urethane wheels support the turntable rotation

- The surface is a chain driven live roller conveyor

- Conveyor is driven by a 1/2 HP gear motor

- Welded safety skirt is provided around the perimeter

- All steel is heavy duty, welded construction

- The complete 90 degree cycle rate is thirty seconds

All conveyors are built with frames and supports welded together, making each section a superstructure, the most rugged standard in the industry.