Conveyor for Wide Loads

Product Details: Item No. 159

Capacity: 6,000 lbs. unit load

Use: For conveying and accumulating heavy loads up to 8’ wide

Material: Stainless, carbon, or galvanized steel construction

- Overview

- Description of Operation

- Technical Specifications

- More Alternative Equipment

- Product Details

Overview

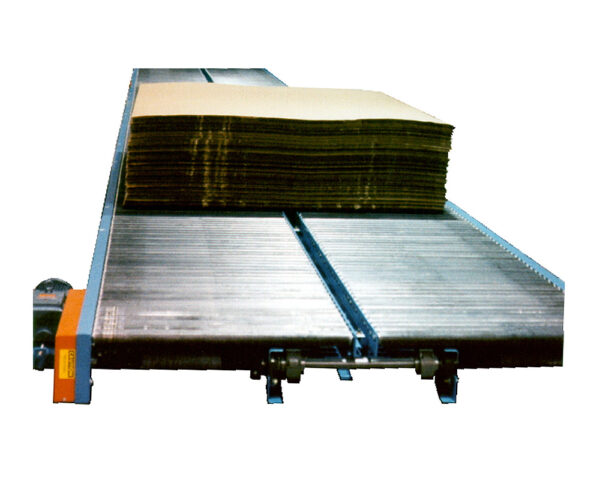

Accumulation conveyor allows the gathering of products in-line and holds them until needed. The photo shows a custom-made, double width, belt driven live roller accumulation conveyor, built to transport and accumulate eight foot wide loads of corrugated material weighing up to 6,000 lbs. There are four, zero pressure zones built into this conveyor to prevent loads from contacting each other. It is also a low profile unit at, 13″ off the floor. Two live roller conveyors, each four foot wide, were built on a common frame to get the needed results.

Description of Operation

This is a custom-made, double width, belt driven live roller, accumulation conveyor.

- A corrugated machine discharges each load onto the accumulation conveyor

- Each load transports to the next available zone in accumulation

- Inspectors look and remove the unfit sheets before the final wrapping operation

- Each wide load accumulates and stops 18″ behind the load in front of it

- Inspectors drop planks across the conveyor to allow them to walk across it.

- Each accumulation zone primes the next empty zone to stop a load when it arrives

- Zones are mechanically disengaged, signaled by the previous vacant zone

Technical Specifications

This is a custom-made, double width, belt driven live roller, accumulation conveyor. It operates in a corrugated plant twenty-four hours per day, seven days a week.

- Two, 4′ wide conveyors built on a common frame

- Rollers are 2.5″ diameter with 11/16″ hex axles

- Rollers are spaced 3″ on centers

- Drive is floor mounted 1½ HP gear motor

- End pulley is 8″ diameter, lagged

- Take-up pulley is 8″ diameter

- Belt is 12″ wide PVC

- Zones are 6′ long, mechanically disengaged

- Frames are 6″ x 8.7 lb/ft structural channels

- Supports are 6″ channels welded to frames

All conveyors, standard and custom made are built with frames and supports welded together, making each section a superstructure, the most rugged standard in the industry.