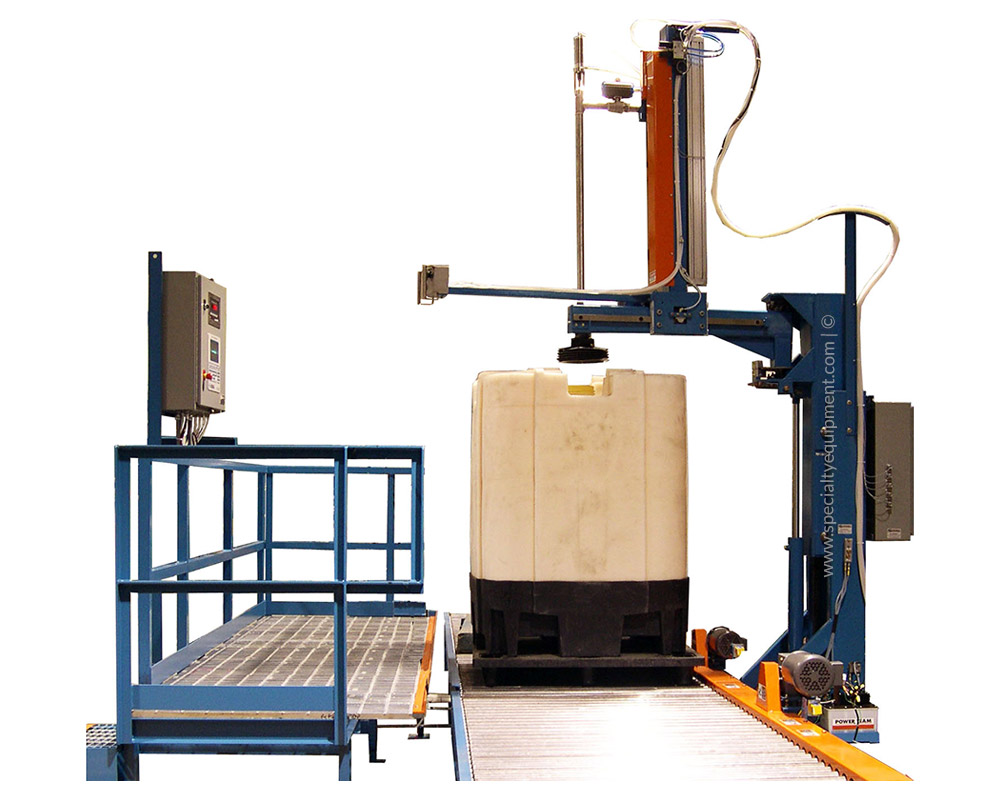

Automatic Tote Filler

Model: ATF-5000

Capacity: One tote or IBC with or without a pallet

Container: 275 to 550-gallon totes or IBC’s

Rate: One 275 gallon filled tote every 5 minutes, or 12 per hour depending on the viscosity of the liquid

Material: Carbon or stainless steel construction all wetted parts use 316 stainless steel

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | No |

| Conveyor System For Empty And Full Containers | Standard |

| Foaming Product | Yes |

| Automation Type | Automatic – Machine positions container to lance |

| Product Temperature | <250 |

| Container Type (Standard) | Totes / IBCs up to 330 gallons (with 5" conveyable foot), Totes / IBCs up to 5,500 gallons (with 5" conveyable foot) |

| Container Type (Optional) | Drum-Plastic, Drum-Steel, Pails, Palletized Drums (Plastic), Palletized Drums (Steel) |

| Fill Heads (Standard) | 1 Fill Head |

| Fill Heads (Optional) | 2 Fill Head |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Classification for Explosive / Flammable Environments (Optional) | Class I – Div I, Class I – Div II |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment, Food Grade, Outdoor, Requires Washdown |

| Frame Construction / Coating (Standard) | Carbon Steel Enamel |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 304, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | Corrosive / Caustic, Food Grade |

| Product Viscosity Handling (Standard) | 0-2,500 CPS (Water to Maple Syrup), 10,000 CPS (Honey), 100,000 CPS (Toothpaste), 50,000 CPS (Ketchup) |

| Product Viscosity Handling (Optional) | 250,000 CPS (Peanut Butter) |

Overview

This rugged liquid filling machine, model ATF-5000, is an automatic tote filler designed to fill 275 to 550-gallon totes, or IBC’s, up to 5,000 lbs. A larger model is available for loads up to 10,000 lbs. Empty containers are conveyed into the filling station and stop with the bung opening under the filling lance. Production rates vary by the liquid viscosity, but a normal 275-gallon tote can be filled with water in less than four minutes with 80 gallons per minute input. The complete cycle rate, about five minutes, is determined by the container entering, filling and discharging from the filling station.

Description of Operation

This automatic liquid filling machine is a model ATF-5000, top-fill and sub-surface filler for a single container from 275 to 550 gallons.

- The bung plug will be removed prior to the load arriving at the filing station

- An empty container will convey into the fill station and signal the conveyor to stop with the opening under the filling lance at the fill station

- If filling a foaming product, the lance travels to the bottom of the tote for sub-surface filling

- If filling a non-foaming liquid, the lance will travel several inches into the container then stop

- The filler will automatically zero tare the container weight before the fill cycle begins

- Filling starts automatically after the weight is tarred

- The filling process has three speeds, if necessary, slow/fast/dribble, to minimize foaming

- Filling continues until the desired weight is achieved.

- When completed the filling information is stored in the computer

- The lance will retract and a drip pan will catch any remaining residue

- A signal is given for the scale conveyor to start

- The full container will convey out and a new empty container will convey into the filling station

- The cycle repeats

Specifications

This automatic liquid filling machine is a model ATF-5000, top-fill and sub-surface filler for a single container from 275 to 550 gallons.

- Lance and all other wetted parts are 316 stainless steel

- Two full-port ball valves to control any water hammering

- Air cylinder raises and lowers the lance

- Scale is 5,000 lb. capacity platform type

- Controller is an Allen Bradley PLC

- Touch screen is an Allen-Bradley color Panelview

- Air operated drip pan with UHMW wiper rings

- NTEP approved scale and weight meter

- NEMA 4 standard panel enclosure, others optional

- Communications port for interface with Drum Filler in the Cloud

- Will automatically zero the tare weights before each fill cycle

- Automatic abort if the lance is not properly aligned with a bung opening

- Operator troubleshooting interface with prompts

- Fills a 275 -gallon tote in less than 4 minutes with water at 80 gallons per minute input

- Cycle rate is determined by drums entering, filling and discharging the filling station

Specialty Equipment manufactures fillers and conveyors with structural steel components welded together, the most rugged standard in the industry.