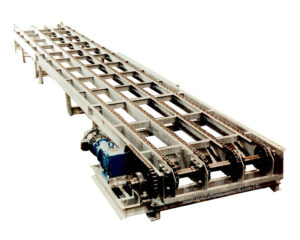

Stainless Gravity Pallet Conveyor

Capacity: 5,000 lbs. per pallet, bin, or IBC load

Use: For conveying and indexing pallets, IBC’s, totes, bins, etc.

Material: Stainless, carbon, or galvanized steel construction

Overview

Stainless Gravity roller conveyor is commonly used for transporting, and accumulating heavy loads, like pallets, bins and totes. This standard, model 2511, gravity roller conveyor is used to transport and accumulate a 5,000 lb pallet load in a plant where wash-down is common, so it is all stainless steel construction. The drive is wash-down duty, rated for a food grade application. Carbon steel conveyor construction is also available.

Description of Operation

Gravity roller conveyors require that bottom boards and runners of a pallet, tote, or bin run in the direction of travel

- This unit is a transport conveyor connected in a line with other similar units

- A pallet, or bin is placed onto the infeed end of this transport line by fork truck

- The pallet rolls by gravity to the end to be picked up by forklift

Specifications

This is an all-stainless steel, model 2511, roll to roll driven live roller conveyor. Stainless gravity roller conveyors require that bottom boards run in the direction of travel

- Washdown ready

- Stainless rollers are 2.5″ diameter with 11/16″ hex axles

- Roller bearings are stainless, food grade, grease packed and sealed

- Rollers are spaced on 5” centers, other spacing available

- Frames are stainless steel, welded 6″ channels

- The inner rail is 4″ stainless angle, welded to frames

- Supports are 4″ stainless channels welded to the frames

- Conveyor capacity is 1,500 lbs per linear foot

All conveyors are built with frames and supports welded together, making each section a superstructure, the most rugged standard in the industry.