Gravity Conveyor for Pallet Jacks

Product Details: Item No. 150

Capacity: 3,000 lbs per pallet or IBC load

Use: For conveying and accumulating pallets, IBC’s, totes, bins, etc.

Material: Carbon, galvanized, or stainless steel construction

- Overview

- Description of Operation

- Technical Specifications

- More Alternative Equipment

- Product Details

Overview

When you don’t have a conventional fork lift, or when space won’t allow fork truck access, you can use a hand pallet jack to pick-up or drop-off heavy loads. This custom made gravity roller conveyor uses 2.5″ diameter rollers for loads up to 3,000 lbs. A ramp must be used to gain elevation and provide a level surface for the pallet load to be at the same level as the pallet jack forks. If a ramp is not available, these conveyors can be placed in a pit in the floor, thereby making the load level with the floor for easy pick up with a pallet jack.

Description of Operation

This gravity roller conveyor must have a ramp-up then-level surface used with the application.

- If a ramp is not available, a pit in the floor will suffice to mount the conveyor

- The pallet must have bottom runners (skis) in the direction of travel

- The operator pushes the pallet jack into the pick up station

- The operator captures the pallet load from the roller surface

- The pallet jack moves back down the ramp

- The same functions are used for dropping off a pallet load

- If mounted in a pit, the operation is simply a drive-in, drive-out process

Technical Specifications

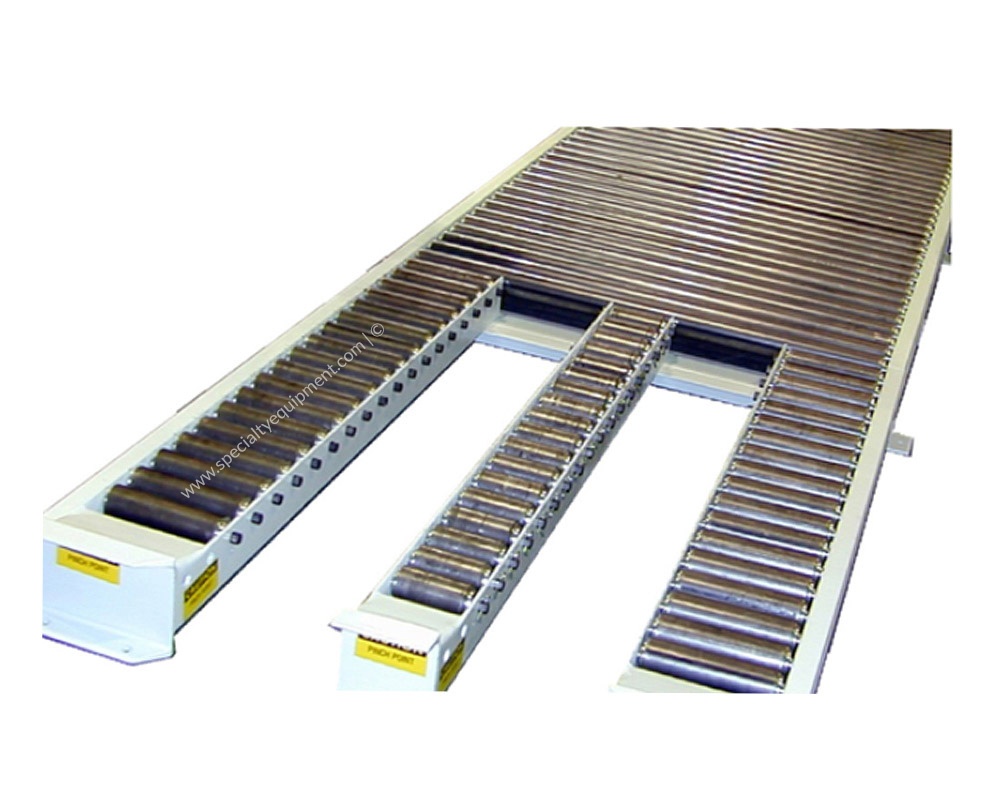

This is a model 2511 gravity roller conveyor, made from three sections and is typically pitched from 1/4” to 1/2” per foot slope depending on the weight and bottom surface of the pallet, bin, or tote being conveyed.

- The two outer sections are 10” between frames gravity roller conveyor

- The inner rail is a 6” between frames gravity roller conveyor

- Conveyor frames are 6″ structural steel channels and 5” angles

- The inner rail is 4″ structural steel angle, welded to frames

- Supports are 4″ structural steel channels welded to the frames

- Rollers are 2.5″ dia. with 11/16″ hex axles

- Rollers are spaced on 3” or 4″ centers

- Welded end stops are included.

- Conveyor is rated for 2,000 lbs per linear foot

All conveyors are built with frames and supports welded together, making each section a superstructure, the most rugged standard in the industry.