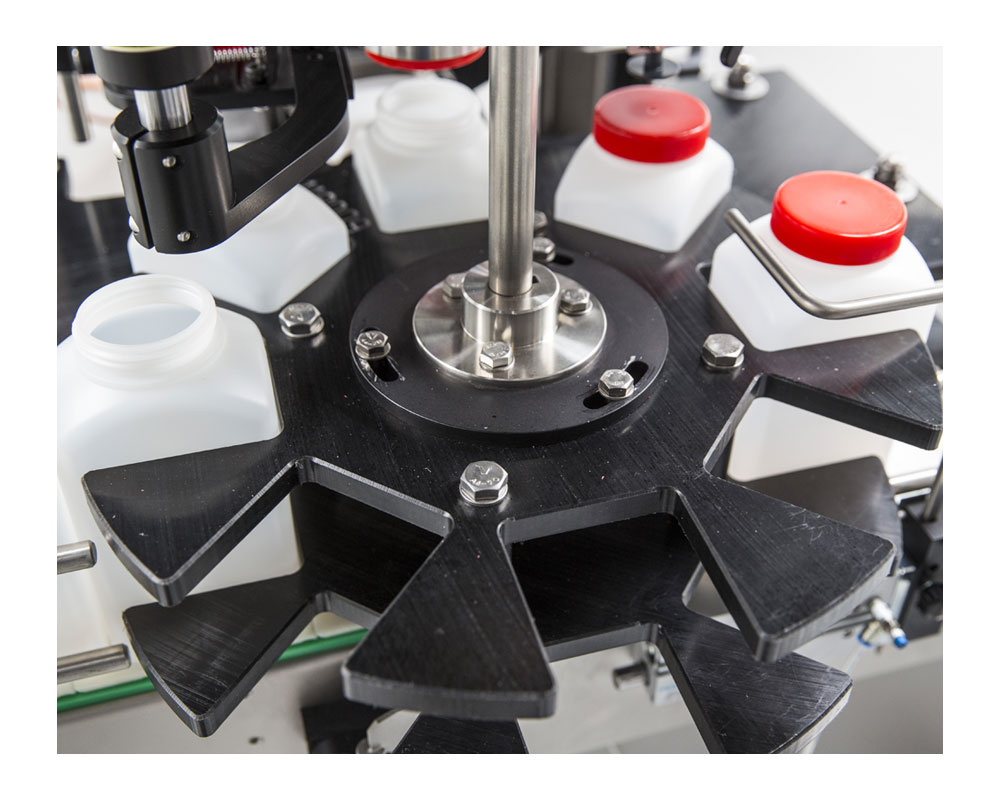

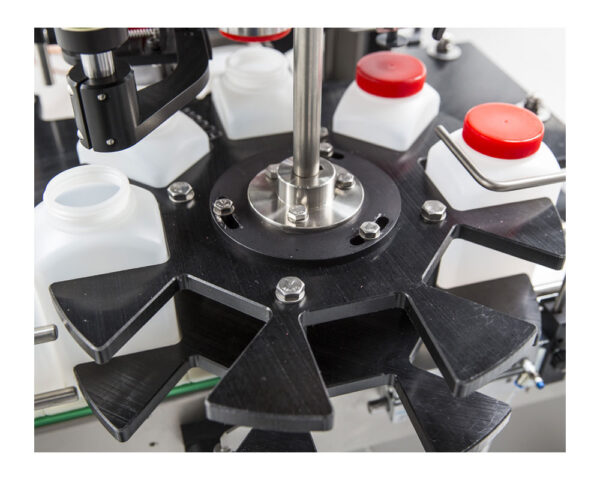

Wisla Automatic Rotary Servo-Driven Bottle Filling System (up to 50 bottles/minute)

Product Details: Item: Wisla

Capacity: 50 ml – 1.5L; 2 oz – 1.25 Quarts

Rate: 50 bottles per minute

Filling Heads: 1-4

Material: Stainless steel construction all wetted parts use 316 stainless steel

Option: Piston or flowmeter

Overview

This Sneyders model is a rugged, fully-automatic bottle filling machine designed to fill up to 50 bottles or quarts per minute. Our rotary filler fills by dosing with pistons, flow meters, or peristaltic pumps. This bottle filler is ideal for the following product lines: personal healthcare/beauty, lubricants, oils, and cleaning products.

Technical Specifications

This automatic liquid bottle filling machine is a sub-surface filler for 2 oz. bottles to 1.25quarts.

- Lance and all other wetted parts are 316 stainless steel

- Linear filling machine for liquid and viscous products

- Accurate, fast, flexible and silent

- All filling movements are servo driven

- Fast product change over with integrated CIP mode

- Product adapted dosing techniques

- Esthetic design complies with most hygienic requirements for both internal and external parts

- Simplified operator panels with easy-to-understand graphics

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | Optional |

| Infeed Conveyor | Optional |

| Filler Conveyor | Included |

| Outfeed Conveyor | Optional |

| Foaming Product | No |

| Sub-surface Filling (for foaming products) | N/A – Top Fill Only |

| Sub-surface Filling Technology | N/A – Top Fill Only |

| Piston / Volume Adjustment | Servo-Driven |

| Automation Type | Fully Automatic – Machine removes and/or replaces bung / lid |

| Product Temperature | 50 Celsius/122 Fahrenheit |

| Container Type (Capacity) | 2oz to 1.5 Quart, 50ml to 1.5L |

| Fill Heads (Standard) | 1 to 4 |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment |

| Site Conditions (Wash Down) | N/A |

| Frame Construction / Coating (Standard) | Stainless 304 |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | PVC |

| CIP | Optional |

| Inline - Rotary | Rotary |

| Capping | Included |

| Pump Requirement | No pump required for < 2 heads |

| Checkweigher to Validate and Maintain / Correct Product Filling Weight | Optional |

| Filling Principle (Volumetric/Flow/Weight/Peristaltic Pump) | Volumetric / Peristaltic |

| Peristaltic Pump Dosing | Optional |