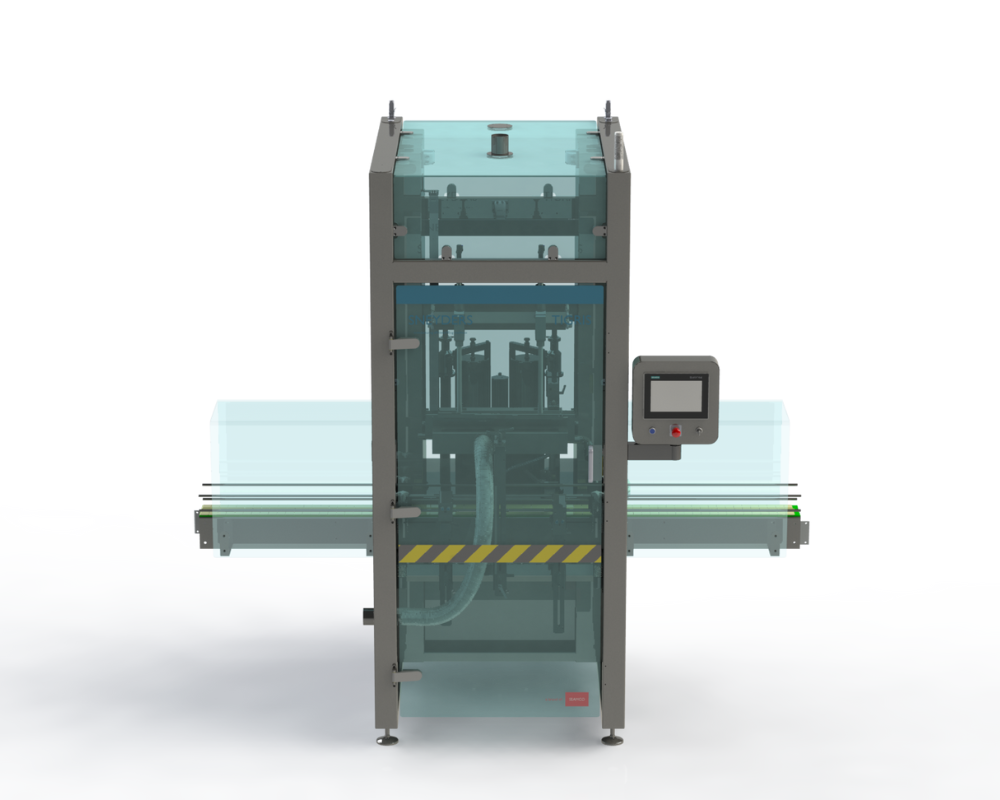

Tigris Automatic Inline Bottle Filler (up to 22 bottles/minute)

Product Details: Item: Tigris

Capacity: 50ml – 10L; 2 oz – 2.5 Gallons

Container: 50ml bottles up to gallon bottles and F-style jugs

Rate: up to 22 bottles per minute depending on the viscosity of the liquid

Filling Heads: 1-4

Material: Stainless steel construction all wetted parts use 316 stainless steel

Option: Piston or flowmeter

Overview

This Sneyders model is a rugged, fully-automatic bottle filling machine designed to fill up to 22 bottles per minute. It can also easily convert to fill a variety of bottle sizes or jugs. Our hygienic bottle filling machine is ideal for the following product lines: personal healthcare/beauty, lubricants, oils, and cleaning products.

Technical Specifications

This automatic liquid bottle filling machine is sub-surface filler for 1 to 4 bottles from 2 oz to 2.5 gallons.

- Lance and all other wetted parts are 316 stainless steel

- Linear filling machine for liquid and viscous products

- Accurate, fast, flexible and silent

- All filling movements are servo driven

- Fast product change over with integrated CIP mode

- Product adapted dosing techniques

- Esthetic design complies with most hygienic requirements for both internal and external parts

- Simplified operator panels with easy-to-understand graphics

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | Optional |

| Infeed Conveyor | Optional |

| Filler Conveyor | Required |

| Outfeed Conveyor | Optional |

| Foaming Product | Possible |

| Sub-surface Filling (for foaming products) | Included |

| Sub-surface Filling Technology | Servo-Driven |

| Piston / Volume Adjustment | Servo-Driven |

| Automation Type | Automatic – Machine positions container to lance |

| Product Temperature | 50 Celsius/122 Fahrenheit |

| Fill Heads (Standard) | 1 to 4 |

| Capacity 1 Liter | Yes |

| Capacity 5 Liter | Yes |

| Capacity 20 Liter | No |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment |

| Site Conditions (Wash Down) | N/A |

| Frame Construction / Coating (Standard) | Stainless 304 |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | PVC |

| CIP | Optional |

| Inline - Rotary | Inline |

| Capping | Optional |

| Pump Requirement | No pump required for < 2 heads |

| Checkweigher to Validate and Maintain / Correct Product Filling Weight | Optional |

| Filling Principle (Volumetric/Flow/Weight/Peristaltic Pump) | Volumetric / Peristaltic |

| Peristaltic Pump Dosing | Optional |