Filler Controls

Product Details: Item No. 30

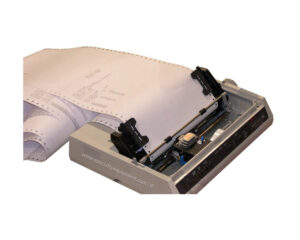

Components: NEMA 4 standard control panel complete with PLC, touch screen, weight meter, AC and DC power supply, all Allen Bradley components, wiring, and programmed – Pneumatic panel is below electrical panel, mounted on the same stand

Material: Carbon or stainless steel panels

Overview

Specialty manufactures all its fillers and conveyor systems with the necessary controls. Each control panel is built, programmed and tested at the plant along with the fillers, conveyors and pneumatic devices to be controlled.

Control panels have been provided in hazardous, corrosive, toxic, flammable, windy, abrasive, wet, and normal conditions. The push button controls necessary for the operator to activate the pail or drum filler are built onto the handle in front of the operator.

Explosion proof control panels are NEMA 4X enclosure and nitrogen purged, rated for class 1, division 1. Specialty also builds stainless steel control panels where wash-down, corrosion, and contamination are concerns.

Technical Specifications

The standard drum filler control panel includes the following:

- NEMA 4 enclosure

- Allen Bradley PLC

- DC outputs and relay outputs

- Allen Bradley color Panel View touch screen

- NTEP approved weight meter

- Ethernet capability

- All Allen Bradley components

- Power distribution block

- Step down transformer

- Fused disconnect

- Trouble shooting prompts

- 250 product menu

- E-stop button

- 120 VAC from step down

- 24 volt DC power supply

- All wires are numbered and tagged at each end

Pneumatic controls are assembled below the electrical panel on the same stand