Palletized Drum & IBC / Tote Filler

The most versatile and widely accepted filling machine is this palletized drum and IBC/tote filler. It is both a top and sub-surface liquid filling machine for filling a pallet of drums or a single IBC/tote ranging from 5 to 550 gallons.

Product Details: Item No. 102

Model: DF-5540

Capacity: 3, 4, or 5 drums per pallet or an IBC

Container: 5 to 55 gallon drums or 275 to 550 gallon IBC’s, containers 20” to 80” tall

Material: Carbon or galvanized steel construction, all wetted parts use 316 stainless steel

Overview

The most versatile and widely accepted filling machine by the chemical, cleaning and coatings manufacturers is this palletized drum and tote filler. This is both a top and sub-surface filling machine for filling a pallet of drums or a single tote. Our filling machine has an inner mast within the stanchion that rises up and down adjusting the boom and lance to the height of any container, ranging from 5 to 550 gallon, or 20″ to 80″ tall. All the necessary controls to operate the filler and conveyors are on the handle in front of the operator.

The video below shows this popular filling machine in use.

Description of Operation

This model DF-5540 is a top and sub-surface filling machine for containers from 5 to 550 gallons, or 20″ to 80″ tall.

- A load of empty containers conveys to the fill station and stops automatically by photo eye

- By pushbutton, the boom is released for the operator to guide the lance to the bung opening of any drum or container

- When the operator releases the button, the boom is automatically locked in place

- By pressing start, the lance travels to the bottom of the drum, if in sub-surface mode

- The machine automatically zeros the tare weight before the fill cycle begins

- When the liquid reaches the lance tip the machine automatically shifts into fast fill cycle

- Near the top, the machine cycles to slow speed to top off the drum and minimize foaming

- When filled to the designated weight, the lance automatically retracts to its home position

- The operator presses the button to release the boom and guide the lance to the next drum

- When all containers are filled, a button will drive out the full and drive in a new load

Technical Specifications

This is a model DF-5540, a sub-surface and a top-fill machine

- Lance and all other wetted parts are 316 stainless steel

- Two infeed full-port ball valves prevent product hammering

- Scale is a 5,000 lb capacity platform type

- Controller is an Allen Bradley PLC with a 250 product menu

- Touch screen is an Allen Bradley color Panel View

- Filler has a three speed filling cycle; slow/fast/shot, if needed

- Air operated drip pan with a UHMW wiper ring

- Fume hood under the lance housing for vapor collection

- Air cylinder to raise and lower the fill lance

- Heavy duty brakes for boom position locking

- NTEP approved scale and weight meter

- NEMA 4 standard enclosure, others optional

- Communications port for interface with Drum Filler in the Cloud

- Filler will automatically zero the tare weight before the fill cycle

- Operator troubleshooting interface with prompts

- Automatic abort if lance is not aligned with bung opening

- Rugged, all-welded structural steel, painted stanchion

- Fills a 55 gallon drum with water in 45 seconds at 80 gallons/minute

Specialty Equipment manufactures fillers and conveyors with structural steel stanchions, frames and supports welded together, making each section a one-piece superstructure, the most rugged standard in the industry.

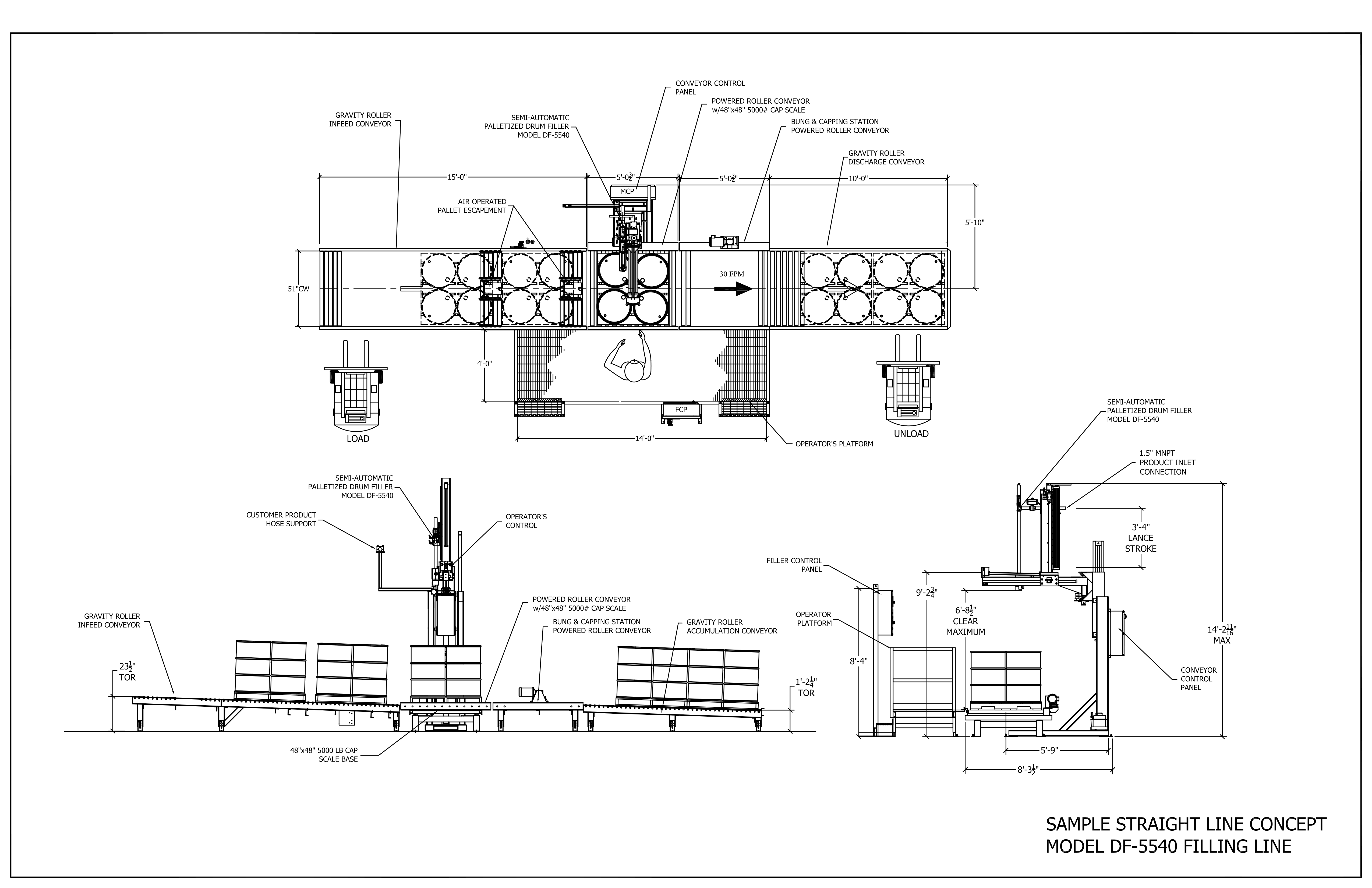

Concept Drawing

A straight-line configuration is the most common palletized drum and tote filling application. This includes pallet accumulation before the filler, one pallet at the filler and another after for bung and capping. Accumulation conveyor for finished loads is built on the end awaiting fork truck pick up.

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | No |

| Conveyor System For Empty And Full Containers | Standard |

| Foaming Product | Yes |

| Automation Type | Semi-Automatic – Operator positions lance to container or container to lance |

| Product Temperature | <250 |

| Container Type (Standard) | Drum-Plastic, Drum-Steel, Palletized Drums (Plastic), Palletized Drums (Steel), Totes / IBCs up to 330 gallons (with 5" conveyable foot) |

| Container Type (Optional) | Pails, Totes / IBCs up to 5,500 gallons (with 5" conveyable foot) |

| Fill Heads (Standard) | 1 Fill Head |

| Fill Heads (Optional) | 2 Fill Head |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Classification for Explosive / Flammable Environments (Optional) | Class I – Div I, Class I – Div II |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment, Food Grade, Outdoor, Requires Washdown |

| Frame Construction / Coating (Standard) | Carbon Steel Enamel |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 304, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | Corrosive / Caustic, Food Grade |

| Product Viscosity Handling (Standard) | 0-2,500 CPS (Water to Maple Syrup), 10,000 CPS (Honey), 100,000 CPS (Toothpaste), 50,000 CPS (Ketchup) |

| Product Viscosity Handling (Optional) | 250,000 CPS (Peanut Butter) |