Chain Conveyors

Product Details: Item No. 147

Capacity: 3,000 lbs per unit load

Use: For wrong-way pallets and loads not conveyable on rollers

Material: Carbon, galvanized, or stainless steel construction

Overview

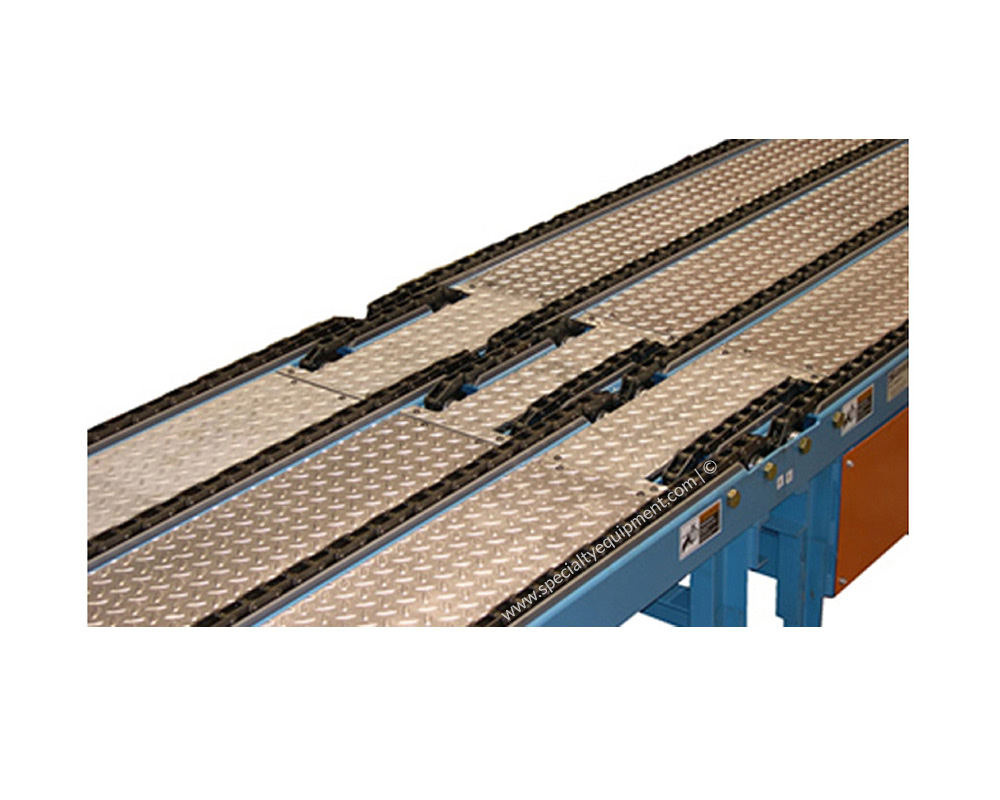

Chain conveyors are used when loads won’t convey on rollers, when load stability is important, when pallet boards or tote runners are going the wrong way, when transferring the load, or when stepping across the conveyor is necessary. Stability is usually a problem with chain conveyors, which is why this four-strand conveyor has special transition sections to transfer loads from one conveyor to another without losing load stability. These transition chains are slave driven from the preceding chain conveyor by sprockets on a common shaft. This unit also has diamond tread walk plates mounted between the strands of chains to allow operators access to crossover the conveyor.

Technical Specifications

This is a multi-strand chain conveyor used when roller conveyors are not suitable, and for transferring heavy loads from roller conveyors. Heavier duty chain conveyors are also available for 5,000 to 10,000 lb. loads

- Frames are made from structural channels, or formed steel plate

- Floor supports are 4” structural channels, adjustable height

- Chains are 2060 double-pitched conveyor roller chain

- UHMW bars are used for chain guides

- B-type drive sprockets, keyed and bored for 2” shafts

- Special slave-driven transfer chain loops at each end

- Diamond tread plates, OSHA approved are used for walkover

- Drive is a 3/4 HP right angle gear motor

- Conveyor speed is 30 ft per minute, others available

- Conveyor capacity is 3,000 lbs per unit load

Conveyors are manufactured with structural steel frames and supports welded together, making each unit a one-piece superstructure, the most rugged standard in the industry.