Automatic Pail Filling System

Product Details: Item No. 115

Rate: 4 to 6 pails per minute, depending on viscosity

Container: 4 to 7 gallon open-mouth pails

Material: Carbon, galvanized, or stainless steel construction, all wetted parts use 316 stainless steel

Overview

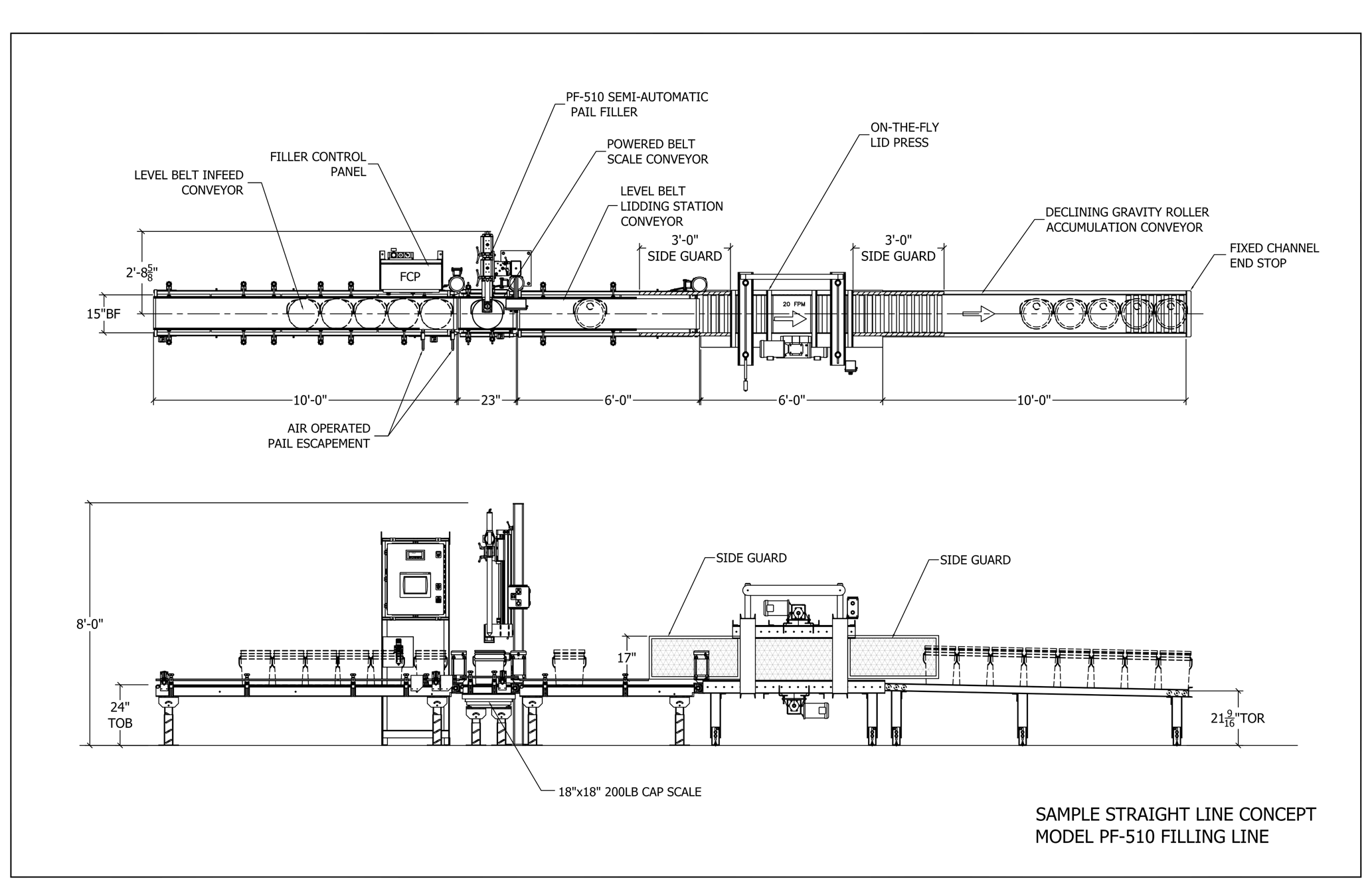

This automatic pail filler was designed for filling open-top, five gallon pails with a viscous liquid in a three-shift operation. Empty pails accumulate to an escapement device and are released when the pail filling machine discharges a full load. The powered conveyor after the filler is for placing lids onto filled pails before they run through the on-the-fly lid press.

An air operated, metal lid crimping device with a cable reel and coiled air line is hanging from a monorail to secure the lids onto occasional metal pails. The monorail allows all pails to continue moving during the securing of the metal lid, or placement of the plastic lids.

The on-the-fly lid press at the end of the line kneads the plastic lid onto the pails as they convey through the tunnel. The tunnel height is adjustable for 4 to 7 gallon containers.

A concept drawing of this pail filling system is shown below.

Description of Operation

The automatic pail filler is a model APF-510

- The infeed is a powered belt conveyor

- A pair of alternating air cylinders are used to automatically escape pails

- The filler is automatically activated when a container arrives

- The scale has a belt conveyor mounted on it

- The lance travels to the bottom of the container

- The controller will automatically zero the tare weight before the fill cycle begins

- The lance retracts automatically ending the fill cycle

- Each pail conveys out of the filler station automatically

- A powered lid placing conveyor allows time for lids to be placed onto each pail

- An automatic lid press seals a lid onto each plastic pail

- The special metal lid crimping tool is mounted on an overhead rail for the operator

Technical Specifications

The filler is a model APF-510, both top and sub-surface filler

- Lance and all other wetted parts are 316 stainless steel

- Two full-port ball valves to control product hammering

- Infeed accumulation and lid conveyors are powered

- The scale conveyor is also powered

- Platform type scale is 200 lb capacity

- Controller is an Allen Bradley PLC with 250 products menu

- Touch screen is an Allen Bradley color Panel View

- NTEP approved scale and weight meter

- NEMA 4 standard enclosure, others optional

- RS-232 port for optional data acquisition and printer connection

- Operator troubleshooting interface with prompts

- Filler won’t start without container present

- Twin air cylinders provide for infeed pail escapement

- Gravity conveyor is used for the discharge accumulation

- Conveyors and the on-the-fly-lid press are optional

- Rugged, welded structural steel, stanchion & conveyors