Automatic Drum Orienting Filler

This filling machine is designed to fill containers without an operator present. It is both a top and a sub-surface filling machine, best applied when an operator is not wanted at the filling station for a variety of reasons, including safety and exposure to fumes or acids.

Product Details: Item No. 110

Model: ADO-5510

Rate: 50 drums per hour

Container: 15 to 55 gallon drums, steel, plastic or fiber, open or tight head

Material: Carbon or stainless steel construction, all wetted parts use 316 stainless steel

Overview

This machine is designed to fill containers without an operator present at the filling station. The system shown is a model ADO-5510. It is both a top-fill and a sub-surface filling machine. This filler is best applied when an operator is not wanted at the filling station for a variety of reasons, including safety and exposure to fumes or acids. Five components make up the system;

- Empty drum pusher device

- Automatic drum rotator

- Up/down tapered plug to lock-in the bung opening

- Automatic single drum filler

- Twin strand chain conveyor

The ADO-5510 filling machine requires bungs to be removed from empty drums before they enter the rotator station. The operational sequence applies to equipment up to and including the filler machine. Optional accumulation conveyor for empty drums is highly recommended to justify the automatic filling operation. Likewise, accumulation of full drums is also highly recommended.

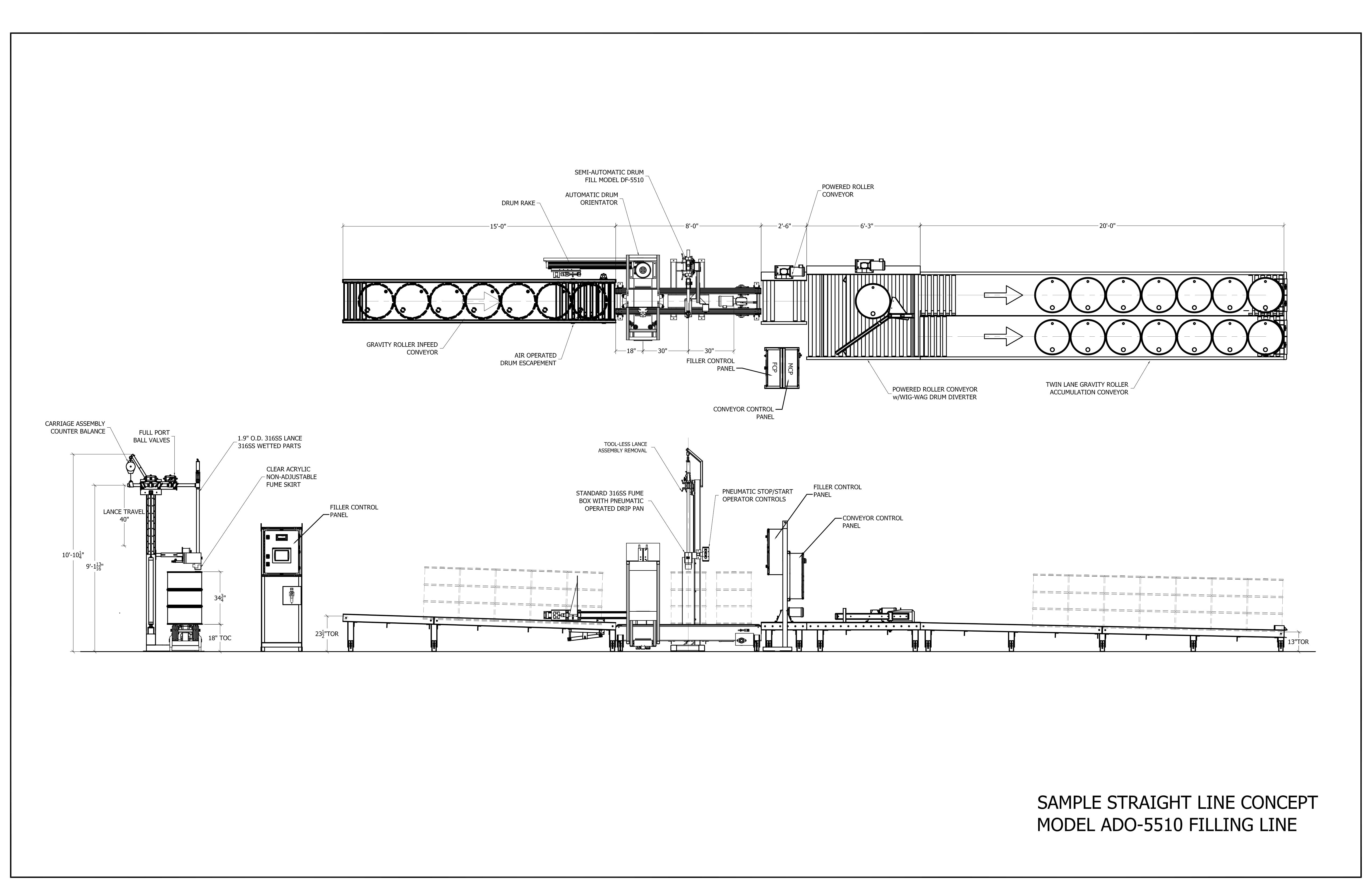

A sample concept drawing of an ADO-5510 straight-line filling system is shown under the Concept Drawing tab.

Description of Operation

- An air operated pusher device moves each container into the rotator station

- A group of skewed rollers lifts the drum off the infeed chain conveyor

- A pneumatic tire and a cradle with wheels captures and centers the drum

- The drum is then rotated automatically in search of the bung opening

- When found, a tapered plug lowers and locks the drum into position

- The drum is lowered onto the chain conveyor then conveyed to the filler station

- The scale raises the container off the chains and signals to start the fill cycle

- The controller will automatically zero the tare weight before the filling starts

- The filler can operate in three speed, slow/fast/shot, if needed

- If filling a foaming product, the system starts in slow mode

- When liquid reaches the tip of the lance, it shifts into fast mode

- Near the top, the system shifts again to shot mode, to the top of the container

- The lance retracts automatically ending the fill cycle

- The scale lowers the container onto the twin strand chain conveyor

- The chain conveyor transports the load to the bung and capping station

- The next empty drum, waiting at the rotator station, automatically advances to the filler

Technical Specifications

This filler is a model ADO-5510 and will fill 15 to 55 gallon drums automatically. This filling machine does not remove or replace bungs. It is both a subsurface and a top-filling machine.

- Lance and all other wetted parts are 316 stainless steel

- Two infeed full-port ball valves prevent product hammering

- Air cylinder raises and lowers the lance carriage

- Scale is 1,000 lb. capacity platform type

- Scale is mounted on an air operated lift/lower mechanism

- Air operated drip pan and UHMW wiper ring

- Controller is an Allen Bradley PLC with 250 product menu

- Touch screen is an Allen Bradley color PanelView

- Communications port for interface with Drum Filler in the Cloud

- NTEP approved weight meter and load cells

- NEMA 4 standard enclosure, others optional

- Filler has three filling speeds; slow/fast/shot, if needed

- Automatic zero tare weight before filling starts

- Operator troubleshooting interface with prompts

- Filler won’t start without container present

- An 8′ long two-strand chain conveyor transports containers

- Automatic abort if lance is not aligned with bung opening

- Rugged, all-welded stanchion and lance carriage

- Fills a 55 gal drum in 45 seconds with water at 80 gallons per minute input

Note: Fillers and conveyors are made with structural steel stanchions, frames and supports welded together, making each section a one-piece superstructure, the most rugged standard in the industry.

Additional information

| Portability | Stationary – Floor mounted |

|---|---|

| Fume Booth | No |

| Conveyor System For Empty And Full Containers | Standard |

| Foaming Product | Yes |

| Automation Type | Automatic – Machine positions container to lance |

| Product Temperature | <250 |

| Container Type (Standard) | Drum-Plastic, Drum-Steel |

| Container Type (Optional) | Pails |

| Fill Heads (Standard) | 1 Fill Head |

| Fill Heads (Optional) | 2 Fill Head, 3 Fill Head, 4 Fill Head |

| Classification for Explosive / Flammable Environments (Standard) | Unclassified |

| Classification for Explosive / Flammable Environments (Optional) | Class I – Div I, Class I – Div II |

| Site Conditions (Standard) | Industrial Standard |

| Site Conditions (Optional) | Corrosive Environment, Food Grade, Outdoor, Requires Washdown |

| Frame Construction / Coating (Standard) | Carbon Steel Enamel |

| Frame Construction / Coating (Optional) | Carbon Steel Epoxy, Stainless 304, Stainless 316 |

| Product - Wetted Parts (Standard) | Standard 316 |

| Product - Wetted Parts (Optional) | Corrosive / Caustic, Food Grade |

| Product Viscosity Handling (Standard) | 0-2,500 CPS (Water to Maple Syrup), 10,000 CPS (Honey), 100,000 CPS (Toothpaste), 50,000 CPS (Ketchup) |

| Product Viscosity Handling (Optional) | 250,000 CPS (Peanut Butter) |